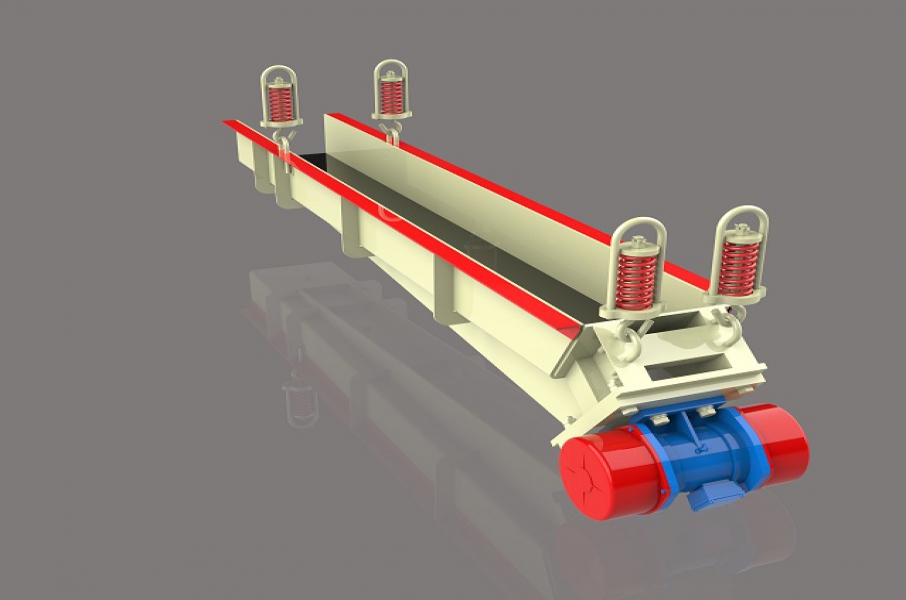

[Introduction]: GZ Series Electromagnetic Vibrating Feeder This feeder is a simple-structured feeder suitable for non-sticky materials. The equipment has a sim

● Product Overview

This feeding machine is a structurally simple machine suitable for non adhesive materials. The equipment has a simple structure, uniform feeding, good continuous performance, adjustable excitation force, and the flow rate can be changed and controlled at any time. It is easy to operate.

[Applicable materials] Uniform, quantitative, and continuous supply of block, granular, or powdered materials

【 Scope of Application 】 Used in industries such as mining, metallurgy, coal, power, chemical, glass, refractory materials, etc

Production capacity: 5-100t/h

● Working principle of the product

The electromagnetic vibration feeder is a relatively complete dual particle oriented forced vibration elastic system, which works in a low critical resonance state. The material in the feeding trough is continuously thrown up during the feeding process and jumps forward along a parabolic trajectory to achieve continuous, uniform, and quantitative feeding. This series of electromagnetic vibration feeders adopts a controllable silicon half wave rectification control method, which is convenient for flow regulation and can achieve centralized and automatic control.

● Product advantages

1. Small size, light weight, simple structure, easy installation, no rotating or sliding parts, no need for lubrication.

2. Discounted prices, minimal malfunctions, low maintenance and operation costs, and economical investment.

3. Adopting the resonance principle of mechanical vibration, it operates in a low critical near resonance state with low energy consumption.

4. During operation, the material continuously jumps forward along a parabolic trajectory, resulting in minimal wear on the material chute.

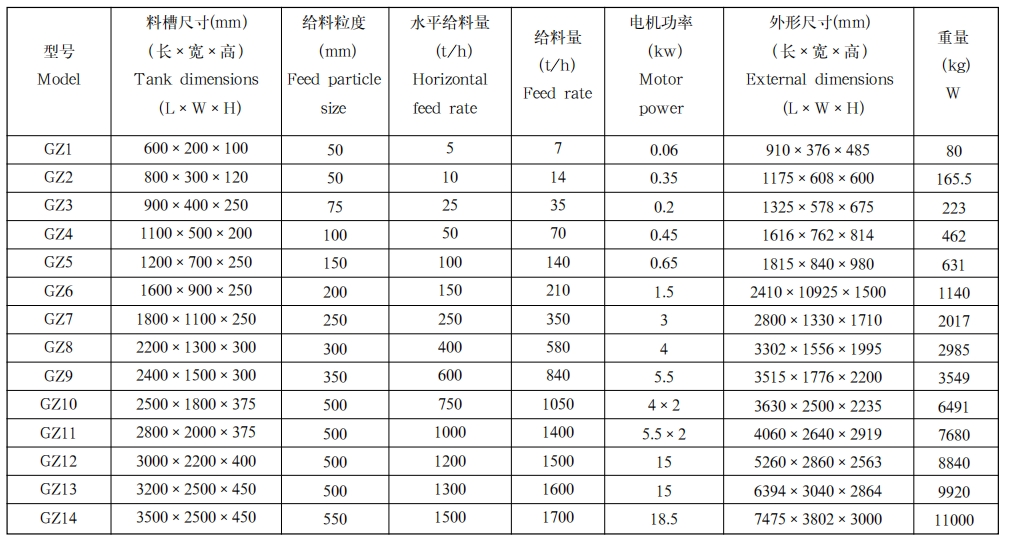

● Product parameters

注:表中给矿能力以堆比重1.6为标准

This machine is an auxiliary device for transportation machinery, suitable for ore dressing plants,

The belt feeder is one of the most commonly used feeding devices. According to the conveying require