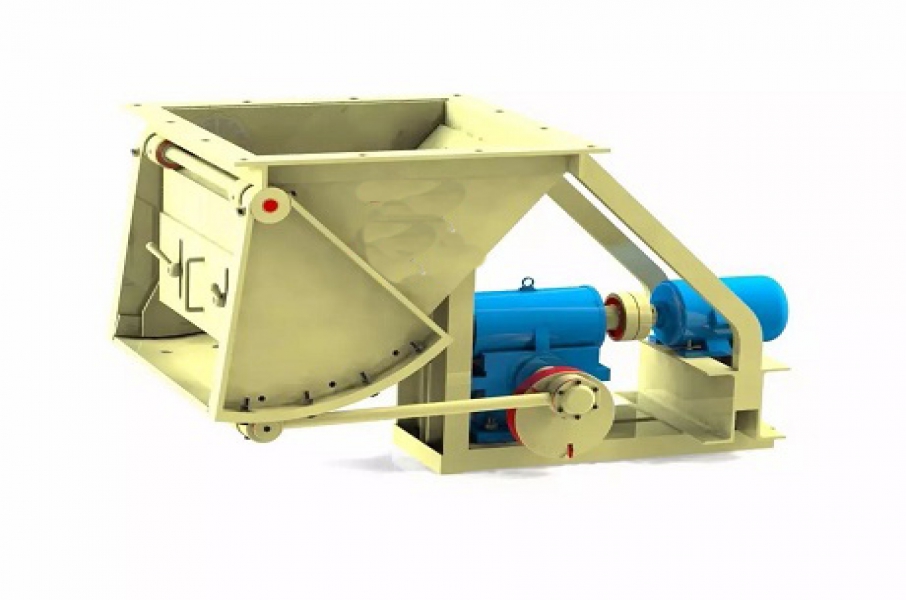

[Introduction]: Swing Feeder This machine is an auxiliary device for transportation machinery, suitable for ore dressing plants,

● Product Overview

This machine is an accessory equipment of transportation machinery, suitable for hanging on steel structural components in departments such as mineral processing plants, smelters, cement plants, sand mines, and mechanized casting workshops. It is installed under the hopper for continuous feeding. Uniform, quantitative, and continuous supply of block, granular, or powdered materials.

Feeding capacity: 4.5-25T/H

Maximum feeding force: 500mm

【 Scope of application 】 Block, granular or powdery materials

Production capacity: 4.5-25T/H

● Working principle of the product

This machine utilizes the principle of eccentric wheel mechanism to make the jaw plate perform periodic reciprocating motion to continuously and uniformly transport the material out. The original driving force relies on the electric motor to drive the eccentric wheel through the turbine reducer, and then the circular motion is converted into reciprocating motion through the connecting rod, driving the jaw plate to reciprocate. When the jaw plate swings clockwise, the material accumulated on it is driven to move together due to friction, and a part of the new material is poured out from the hopper to fill the space formed outside the body. When the jaw plate moves counterclockwise, the internal material is blocked and cannot enter the body with the jaw plate anymore. Therefore, it is pushed into the feeding hopper of the conveying pipe or conveyor set below it. In short, with the periodic swing of the jaw plate, the material can be continuously and uniformly fed.

● Product advantages

It is installed below the storage tank or funnel to transport dry and non caking materials with a particle size not exceeding 50mm, such as ores. But it is not suitable for conveying powdered materials, which can easily cause blockage and affect the feeding. At the same time, it can also cause powder to fly and affect the cleanliness of the workplace. When the machine is not working, it can also be used as a lock.

● Product parameters

A traditional continuous feeding device for powdery materials. The pan feeder is suitable for feedin

This feeder is a simple-structured feeder suitable for non-sticky materials. The equipment has a sim