[Introduction]: Pan Feeder A traditional continuous feeding device for powdery materials. The pan feeder is suitable for feedin

● Product Overview

A traditional continuous feeding equipment for powdered materials.

【 Application Scope 】 The disc feeder is suitable for feeding various non viscous materials and is not suitable for powdery materials with good fluidity. Suitable for departments such as mineral processing plants, smelters, cement plants, sand mines, and mechanized casting workshops to suspend on steel structural components and install them for continuous feeding under hoppers.

Processing capacity: 0-88.4t/h

● Working principle of the product

Bulk materials are loaded into the receiving cylinder from the hopper, and the materials are piled up on the disc by the self weight of the receiving cylinder wall. By adjusting the gap between the sleeve and the disc with adjusting bolts, the natural stacking angle of the materials on the disc can be controlled. When the disc rotates, the material is evenly scraped out of the disc by the discharge knife on the disc and falls down. As the disc rotates, the material is evenly scraped into the receiving hopper by the discharge knife. The continuous operation of the disc completes the uniform feeding operation. Adjusting the gap between the discharge knife and the disc can also control the amount of material fed. During operation, the electric motor drives the disc mounted on the worm gear reducer to rotate through the pulley.

● Product advantages

1. The disc feeder runs stably and is easy to operate;

2. Widely applicable, energy-saving and efficient;

3. High load-bearing capacity and smooth operation;

4. It has the advantages of simple structure, uniform feeding, and reliable use. If the distance between the adjustment sleeve and the disc is changed, the feeding amount can be adjusted.

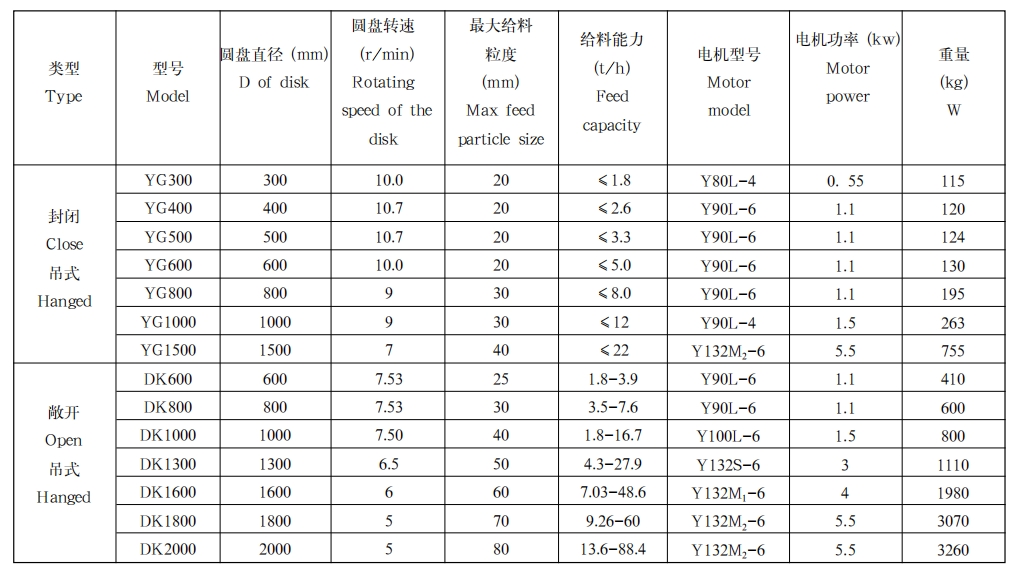

● Product parameters

The trough feeder (also known as a trough ore feeder) can be installed on the ground or suspended at

This machine is an auxiliary device for transportation machinery, suitable for ore dressing plants,