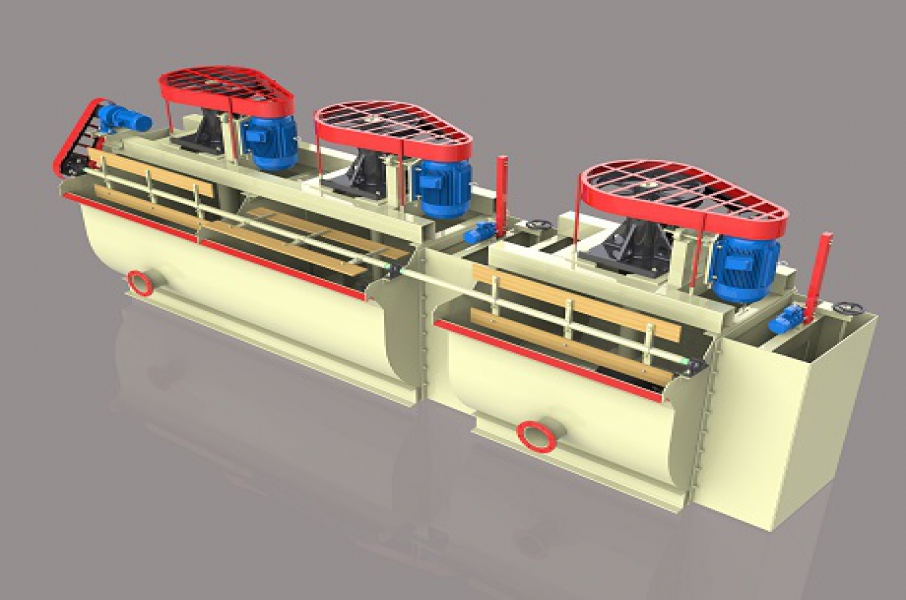

● Product Overview

XCF has the ability of self-priming pulp and can be horizontally configured. It does not need a foam pump, but its power consumption is slightly higher than that of KYF, while KYF has no ability of self-priming pulp and its power is lower; Therefore, XCF and KYF are generally configured as units. XCF is a suction tank and KYF is a direct flow tank. The combined unit can be horizontally configured without foam pump.

【 Applicable Materials 】 Widely used for the selection of non-ferrous metals, ferrous metals, and non-metallic minerals

【 Scope of Application 】 Suitable for coarse and sweeping operations in large and medium-sized flotation plants

[Processing capacity] 0.2-50 m3/min

● Working principle of the product

When the XCF flotation machine is working, with the rotation of the impeller, the slurry in the tank is sucked from the bottom of the impeller through the bottom of the tank to between the impeller blades. At the same time, low-pressure air supplied by the blower enters through the hollow shaft and the air distributor in the impeller chamber. After the slurry and air are fully mixed between the blades, they are pushed out diagonally upward from the upper half of the impeller, stabilized and directed by the stator, and then enter the entire slot. The bubbles rise to the foam stable zone, and after the enrichment process, the foam flows from the overflow weir and flows into the foam tank. A portion of the slurry flows towards the lower part of the impeller, where it is stirred and re mixed to form mineralized bubbles. The remaining slurry flows to the next tank until it eventually becomes tailings.

● Product advantages

XCF and KYF flotation machines are both inflatable flotation machines with small impeller diameter and low circumferential velocity, which can reduce power by 30-50%; There is an air distributor inside the slot, so the air is evenly dispersed; The impeller functions as a centrifugal pump, allowing solid particles to be fully suspended; Adopting a U-shaped groove structure can minimize the sedimentation of tailings; The impeller structure and blade clearance flow reversal design are reasonable, the impeller wear is relatively uniform, and the service life of the impeller and stator is long.

KYF type has no self-priming slurry ability and low power; The XCF type has the ability of self-priming slurry and can be horizontally configured without foam pump. The difference is that a stator is specially set above the impeller to form a special negative pressure zone, but the power consumption is slightly higher than KYF. Therefore, XCF type and KYF type are generally configured as units. XCF type is a suction tank and KYF type is a DC tank. Combined units can be horizontally configured without foam pump.

The XCF II/KYF II flotation machine combined unit adopts a "U" - shaped tank body, hollow shaft inflation and suspended stator, especially a new type of impeller. This is a conical impeller with blades tilted back at an angle, similar to a high specific speed centrifugal pump impeller. It has a large slurry lifting capacity, small pressure head, low power consumption, and a simple structure. At the same time, the air dispersion is good, and the impeller acts as a centrifugal pump, keeping the solids suspended in the tank. It is easy to operate and manage.

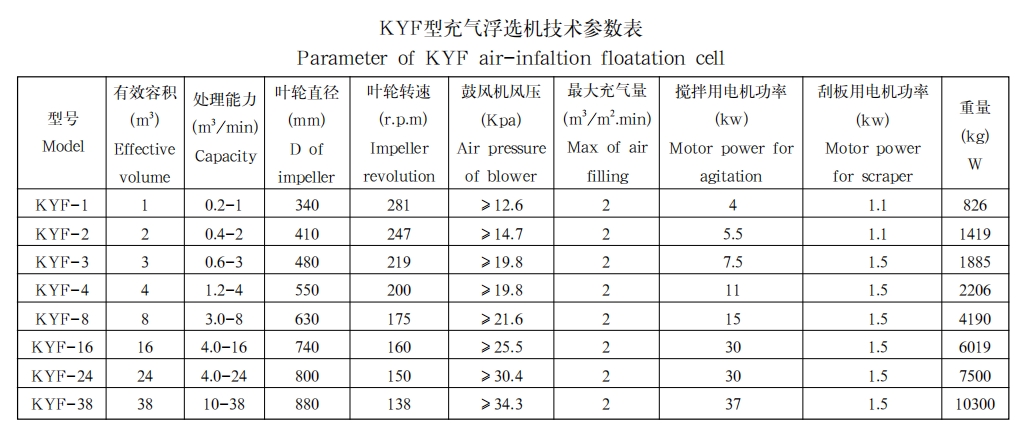

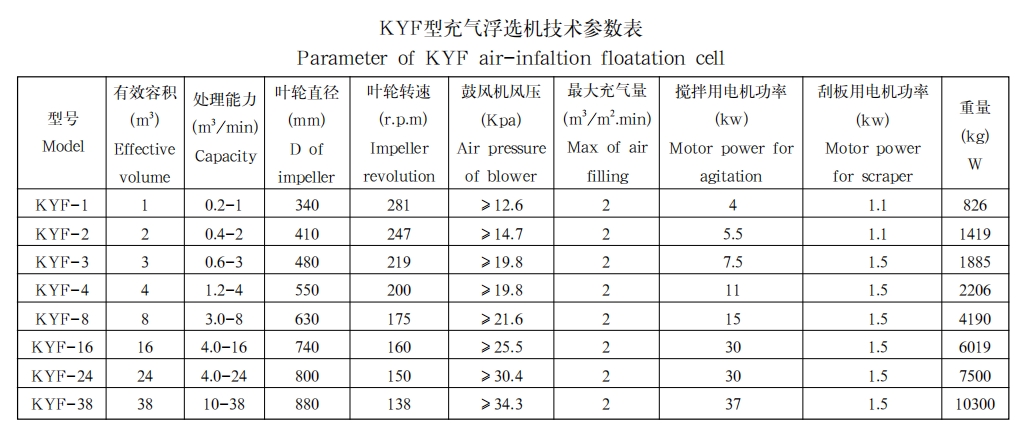

● Product parameters

0535-6350765

0535-6350765