● Product Overview

The main feature of a rod flotation machine is the use of inclined rod wheels, convex platforms, and arc-shaped stabilizing plates to form an inflatable agitator group. Due to the fact that this mixer can prevent sedimentation at the bottom of the flotation tank and has a small dead angle, the volume of the flotation tank can be fully utilized, significantly improving the volume utilization rate.

[Applicable materials] High density and coarse particle ores, especially for the selection of lead, zinc, copper, molybdenum, sulfur, and silica sand

【 Scope of Application 】 Flotation operations in small and medium-sized beneficiation plants

Processing capacity: 1.5-4 m3/min

● Working principle of the product

In the flotation machine, the slurry treated with chemicals is stirred and aerated to selectively fix some of the mineral particles onto the bubbles; It floats to the pulp surface and is scraped out to form foam products, while the rest is retained in the pulp to achieve the purpose of separating minerals.

● Product advantages

The main feature of a rod flotation machine is the use of inclined rod wheels, convex platforms, and arc-shaped stabilizing plates to form an inflatable agitator group. Due to the fact that this mixer can prevent sedimentation at the bottom of the flotation tank and has a small dead angle, the volume of the flotation tank can be fully utilized, significantly improving the volume utilization rate. Due to the W-shaped movement trajectory of the aerated slurry, the installation depth of the rod wheel in the groove can be reduced. This not only makes it easier to start after a long period of parking, but also helps to increase the aeration volume, reduce power consumption, and improve the technical performance of the flotation machine.

In addition, the flotation machine also has the advantages of simple structure, easy operation and maintenance, high bubble dispersion, multiple opportunities for slurry gas contact, uniform mixing, and fast flotation speed.

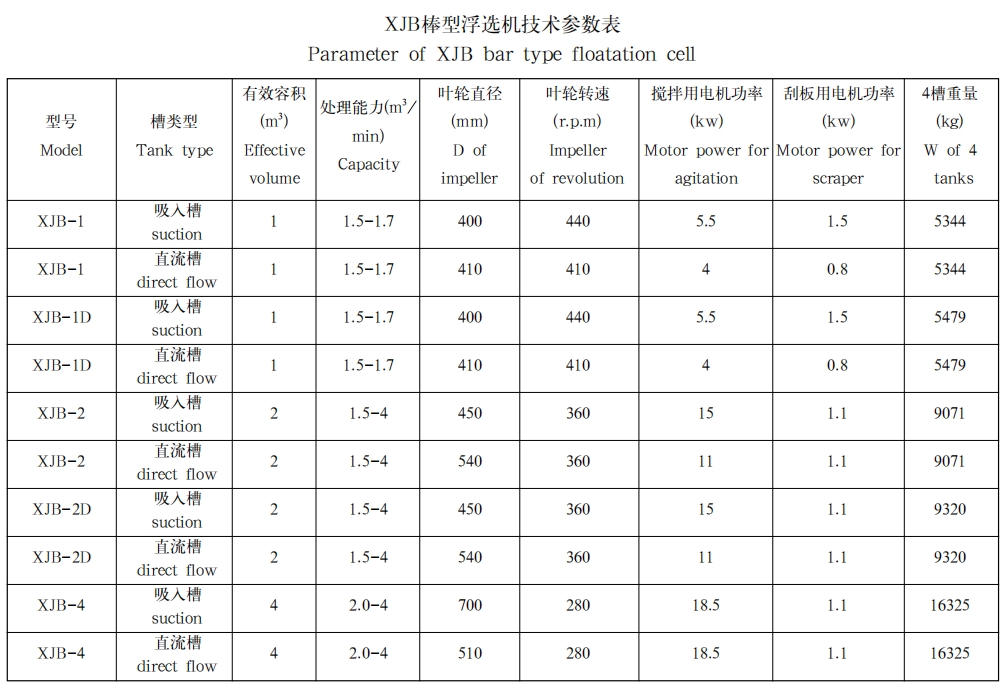

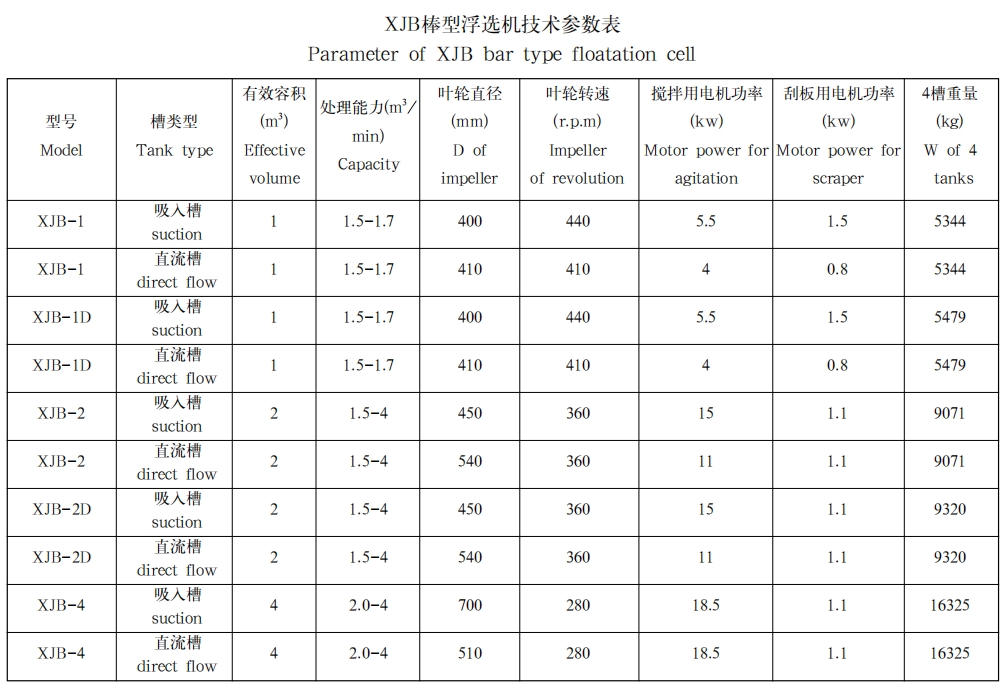

● Product parameters

0535-6350765

0535-6350765