● Product Overview

The BSK series compressed air flotation machine is suitable for material selection of various non-ferrous metal minerals such as copper, lead, zinc, nickel, molybdenum, gold, etc. in mineral processing plants. It can also be used for the separation of ferrous metals (iron) and non-metallic minerals (coal, fluorite, talc, quartz sand)

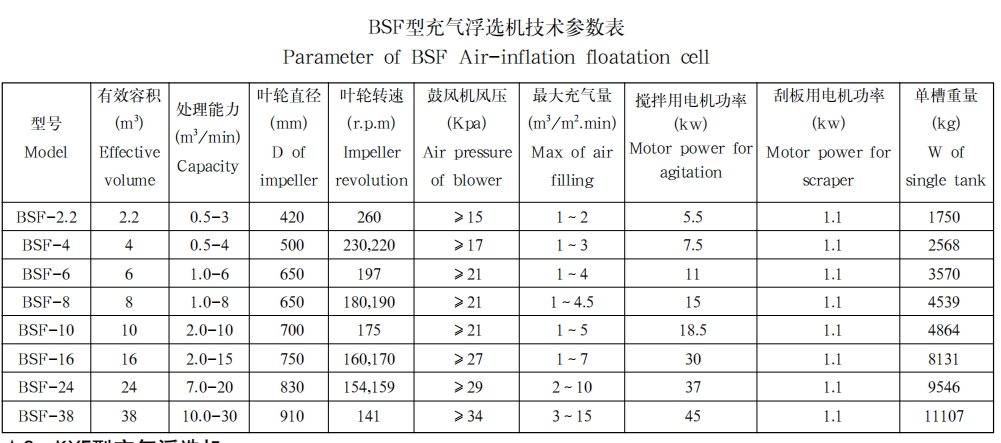

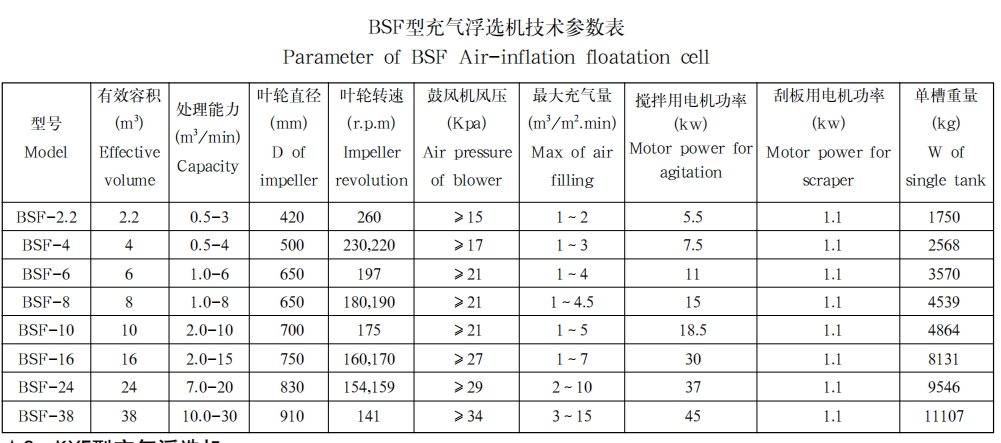

Effective Capacity: 2.2-70 ㎡

[Applicable materials] Material selection for non-ferrous metal minerals, black metal and non-metal separation

【 Processing capacity 】 0.5-50m ³/min

● Working principle of the product

This type of flotation machine adopts a "U" - shaped tank hollow shaft inflation and suspended stator, especially a new type of impeller, a conical impeller with backward inclined blades, which can lift a large amount of slurry, has a small pressure head, low power consumption, and a simple structure. The impeller chamber is equipped with a porous cylindrical air distributor. Air can be evenly dispersed in most areas of the impeller blades in advance, with a large interface between the slurry and air.

When the flotation machine is in operation, with the rotation of the impeller, the slurry in the tank is sucked from the bottom of the impeller through the bottom of the tank to between the blades of the impeller. The low-pressure air supplied by the blower enters through the hollow shaft and the air distributor in the impeller chamber. After the slurry and air are fully mixed between the blades, they are pushed out diagonally upward from the upper half of the impeller, stabilized and directed by the stator, and then enter the entire tank. The bubbles rise to the foam stable area, and overflow from the overflow weir after mineralization enrichment. The other part of the slurry flows towards the lower part of the impeller, and after stirring, it mixes again to form mineralized bubbles. The remaining slurry flows to the next tank until it eventually becomes tailings.

● Product advantages

1) Adopting a U-shaped groove, stirring evenly and not easily depositing;

2) Lightweight structure and easy adjustment;

3) The impeller has a parabolic cross-section, strong stirring force, and easy load start-up;

4) Low energy consumption, can save 30% -40% electricity;

5) The air is evenly dispersed, the foam is stable and suspended, and does not sink.

● Product parameters

0535-6350765

0535-6350765