[Introduction]: High-Frequency Vibrating Fine Screen The high-frequency vibrating fine screen, also known as the "high-frequency screen," is a device for

product overview

High frequency vibrating fine screen, abbreviated as "high-frequency screen", is a device with high frequency and low amplitude for material dewatering and classification. It has high vibration intensity, high frequency, light weight, stable and reliable operation, and large processing capacity. It is suitable for fine coal grading dewatering and coal slurry recovery.

[Scope of Application] Can be used in various industries

[Applicable materials] Fine materials and materials containing a certain amount of moisture, such as plastic, aluminum, zinc, metal ash, sand, soil, etc

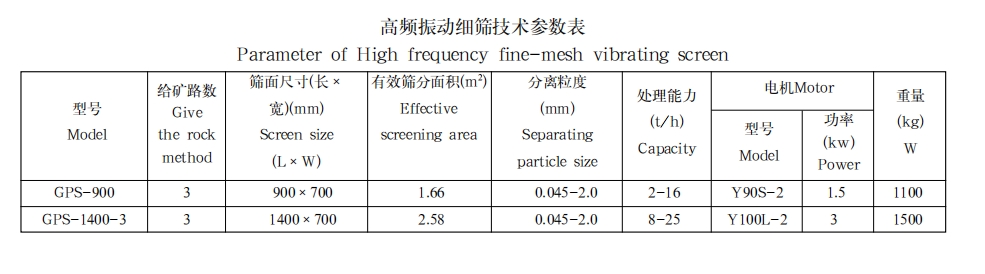

Production capacity: 2-25t/h

● Product Structure

There are two main types of high-frequency vibrating fine screens: stainless steel woven screen mesh and nylon screen mesh. The screening surface is divided into three sections, which can be used for mining simultaneously. In order to ensure that the slurry volume, mass fraction, and particle size of each section of the sieve are basically similar, a slurry distributor is installed. The slurry flowing down through the pipeline from the distributor is evenly fed onto the sieve surface through a uniform plate and a porous rubber plate. The screen surface is made of stainless steel wire woven mesh, which is assembled by overlapping three layers of screens with different aperture sizes. The top sieve has the smallest pore size and is the main sieve, determined by the particle size of the sieve; The second layer of sieve has a larger pore size than the upper layer, which is called an anti clogging sieve; The third layer has larger sieve holes to provide support. The three-layer screen mesh is stretched into one piece and then horizontally tensioned and fixed on the screen frame.

● Working principle of the product

Two motors are used to drive two vibrators in synchronous reverse operation through a tape coupling. The centrifugal force generated by the two eccentric blocks always cancels each other out along the vibration direction, forming a single excitation force along the vibration direction. The sieve box vibrates in a reciprocating straight line at a 50 degree angle to the horizontal plane. Under the action of excitation force, the material undergoes continuous oblique upward throwing motion on the screen surface. Under high vibration intensity, the collision between the thrown material and the screen surface destroys the surface tension of the outer water film of the particles, achieving the purpose of solid-liquid separation.

It generally has three screening surfaces, which are divided into three paths by the slurry distributor and fed into sections at the same time. The screen mesh is fixed on the screen frame and supported by springs and brackets in a suspended state. The vibrator is installed in the upper part of the screen frame to directly drive the vibration of the screen frame.

● Product advantages

1. Compact structure and high overall rigidity.

2. It has a relatively small volume, a large processing capacity per unit area, and is convenient for system process layout.

3. Relatively low energy consumption and high dehydration rate.

4. Easy installation and adjustment, easy replacement.

5. Screen structure and type model block design, easy to replace.

● Product parameters

It uses embedded nylon screen meshes, which are wear-resistant, not easily damaged, and have strong

The system uses a new principle and is a new type of vibrating screen with a vibrating screen surfac