[Introduction]: TD75 Fixed Belt Conveyor This screw conveyor is mainly used for conveying powdery, granular, and small-block materials such a

● Product Overview

This screw conveyor is mainly used for conveying powdery, granular and small block materials, such as coal powder, furnace ash, etc. It has a large carrying capacity and is safe and reliable. Advantages such as strong adaptability, easy installation and maintenance, and long service life.

[Applicable Materials] This screw conveyor is mainly used to transport powdery, granular, and small block materials, such as coal powder and furnace ash

【 Scope of Application 】 Chemical, building materials, grain and other departments

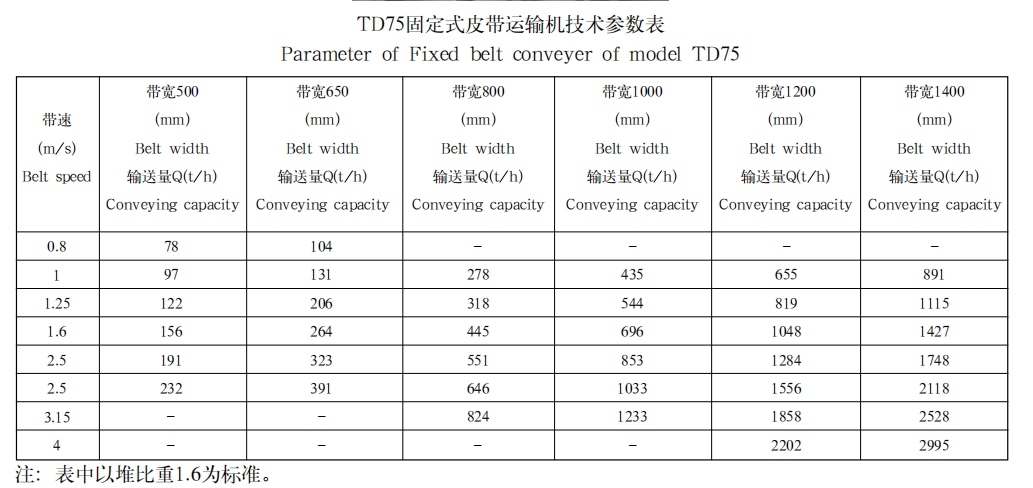

【 Transport Capacity 】 4.5-139t/

● Product Structure

● Working principle of the product

A fixed screw conveyor uses a rotating screw to move the conveyed material along a fixed casing for conveying work. The head and tail bearings are moved outside the casing. The suspension bearings of the fixed screw conveyor use sliding bearings and are equipped with dust-proof sealing devices. The bearings of the fixed screw conveyor are generally made of powder metallurgy. Felt bearings are used for conveying cement, and the suspension shaft and screw shaft are connected by sliding blocks.

● Product advantages

1. The screw conveyor has a large carrying capacity and is safe and reliable. Strong adaptability, easy installation and maintenance, long service life;

2. The whole machine has a small volume, high speed, and ensures fast and uniform conveying. The discharge end is equipped with a cleaning device, which has low overall noise and strong adaptability. The layout of the inlet and outlet positions is flexible;

3. Good sealing performance, the shell is made of seamless steel pipe, and the ends are connected to each other with flanges to form a whole, with good rigidity;

4. The connection between the screw shaft of the screw conveyor and the suspension bearings, head and tail shafts adopts an embedded tongue type, which does not require axial movement for installation and disassembly, making maintenance convenient. The core shaft is long, there are few hanging parts, and there are few fault points;

5. Adopting a variable diameter structure to increase the volume of the suspension bearing and avoid contact between the suspension bearing and the material, the service life of the suspension bearing can reach more than two years; Each transmission part adopts a floating connection method, and the suspension bearing is a universal joint structure, which forms a whole rotating floating body with the spiral body, suspension bearing, and tail assembly. Within a certain range, it can rotate freely with the conveying resistance to avoid material jamming or blockage.

● Product parameters

The bucket elevator is a continuous conveying machine that uses a series of buckets evenly fixed on