[Introduction]: HQ Series Mobile Belt Conveyor The HQ intelligent counter uses "through-beam" infrared sensors to accurately count the number of ob

● Product Overview

The HQ intelligent counter adopts a "paired" infrared sensor, which accurately determines the number of meters based on the "long time" of the object passing through the sensor. It has the advantages of strong anti-interference ability, no loss of numbers in case of power failure, and easy installation and use.

[Applicable Materials] Used for loading, unloading, and transporting loose and packaged materials such as soil, sand, coal, crushed stone, grains, etc

【 Scope of Application 】 Chemical plants, cement plants, fertilizer plants, feed plants, flour mills, grain storage warehouses, docks, station freight yards

【 Conveying Capacity 】 5-20m

● Product Structure

● Working principle of the product

The HQ intelligent counter uses a "paired" infrared sensor to accurately determine the counting quantity based on the "duration" of the object passing through the sensor. The paired infrared sensor is installed and fixed on both sides of the conveyor belt, with one emitting infrared and the other receiving infrared. When the bag passes through the middle and blocks the infrared, the counter will sense the signal and count.

● Product advantages

1. Strong anti-interference ability: When foreign objects fly over the sensor or accidentally obstruct it, the counter will not count;

The counter host has 2 display windows:

Single cumulative window: used to display real-time single count values;

Total cumulative window: used to display the cumulative value of each count;

2. Easy to install and use: Ready to use "foolproof" device that requires no debugging;

3. No loss of count after power failure: continue counting the state before power failure after power on;

4. Setpoint control: Interlocking control with belt conveyor: The counter can control the stop of the belt conveyor (or packaging machine);

5. Advance warning: It can be equipped with an external sound and light alarm. When the package count reaches the set value 10 packages in advance, an alarm will be triggered, providing sound and light alarm prompts;

6. Reset: You can reset it by pressing the key on the host; It can also be set to automatic loop mode. After reaching the set value and delaying for a certain period of time, it will automatically reset and restart;

7. External large screen display: An external large screen display is used to synchronously display real-time single count values, which are the same and synchronized as the single cumulative window; Enlarge the counting numbers for easy viewing by customers or workers.

8. Wireless remote control: It is possible to control the start, stop, and reset of counters and conveyor belts through wireless remote control.

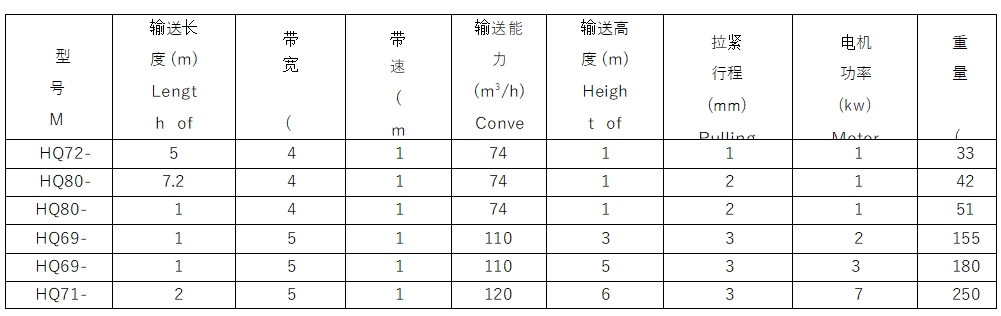

● Product parameters