[Introduction]: Hammer Crusher The hammer crusher is mainly used in the medium crushing process. Its structure is relatively simple

● Product Overview

The hammer crusher is mainly used in the intermediate crushing process, and its structure is relatively simple. It mainly consists of a body, a top cover, a rotor equipped with a ring hammer, a sieve plate, and a sieve plate adjustment device.

Production capacity: 5-150m ³/h

【 Applicable fields 】 Cement plants, metallurgical departments, power departments, building materials, mining, road construction and other industries

【 Scope of application 】 Limestone, slag, coke, coal, salt, chalk, gypsum, alum, iron ore, non-ferrous metal ores, etc

● Product Structure

The hammer crusher is mainly used in the intermediate crushing process, and its structure is relatively simple. It mainly consists of a body, a top cover, a rotor equipped with a ring hammer, a sieve plate, and a sieve plate adjustment device. The motor drives the rotor directly in the studio through an elastic coupling. The rotor is composed of main shaft, end plate, ring hammer and other components. The motor drives the rotor to rotate at high speed to achieve the function of crushing materials. The machine body is composed of upper and lower casings, crushing plates, screen plates and other components. The crushing plates and screen plates are installed on the pallet. The lining plate is installed on the inner walls of both sides of the casing to prevent wear and tear. The crushing chamber is formed by a crushing plate, a sieve plate, a counterattack plate, and a rotor, and an adjusting device is composed of a worm, turbine, pointer, etc.

● Working principle of the product

The motor drives the rotor to rotate at high speed inside the crushing chamber, and the material is fed into the machine from the upper feeding port. It is crushed by the impact, shearing, and grinding of the high-speed moving hammer. At the lower part of the rotor, there is a sieve plate. The particles smaller than the sieve hole size in the crushed material are discharged through the sieve plate, while the coarse particles larger than the sieve hole size are retained on the sieve plate and continue to be hit and ground by the hammer. Finally, they are discharged outside the machine through the sieve plate.

● Product advantages

The crushing ratio is large (usually 10-25, with some reaching up to 50), the production capacity is high, the product is uniform, there are few excessive phenomena, the energy consumption per unit product is low, the structure is simple, the equipment is lightweight, and the operation and maintenance are easy.

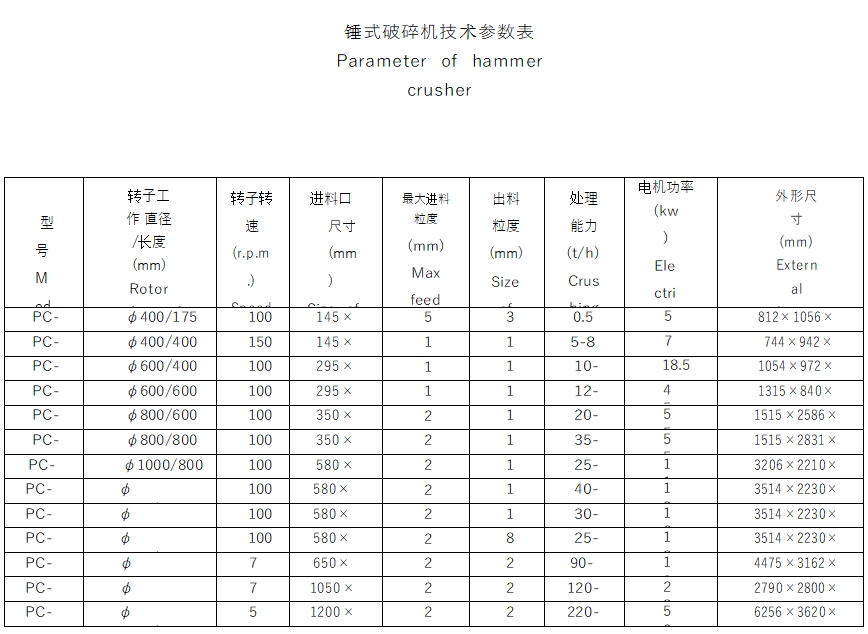

● Product parameters

A medium and fine crushing machine, where the spring serves both as a safety device and affects the

The JYP new type cone crusher is developed by our company after years of technical research and deve