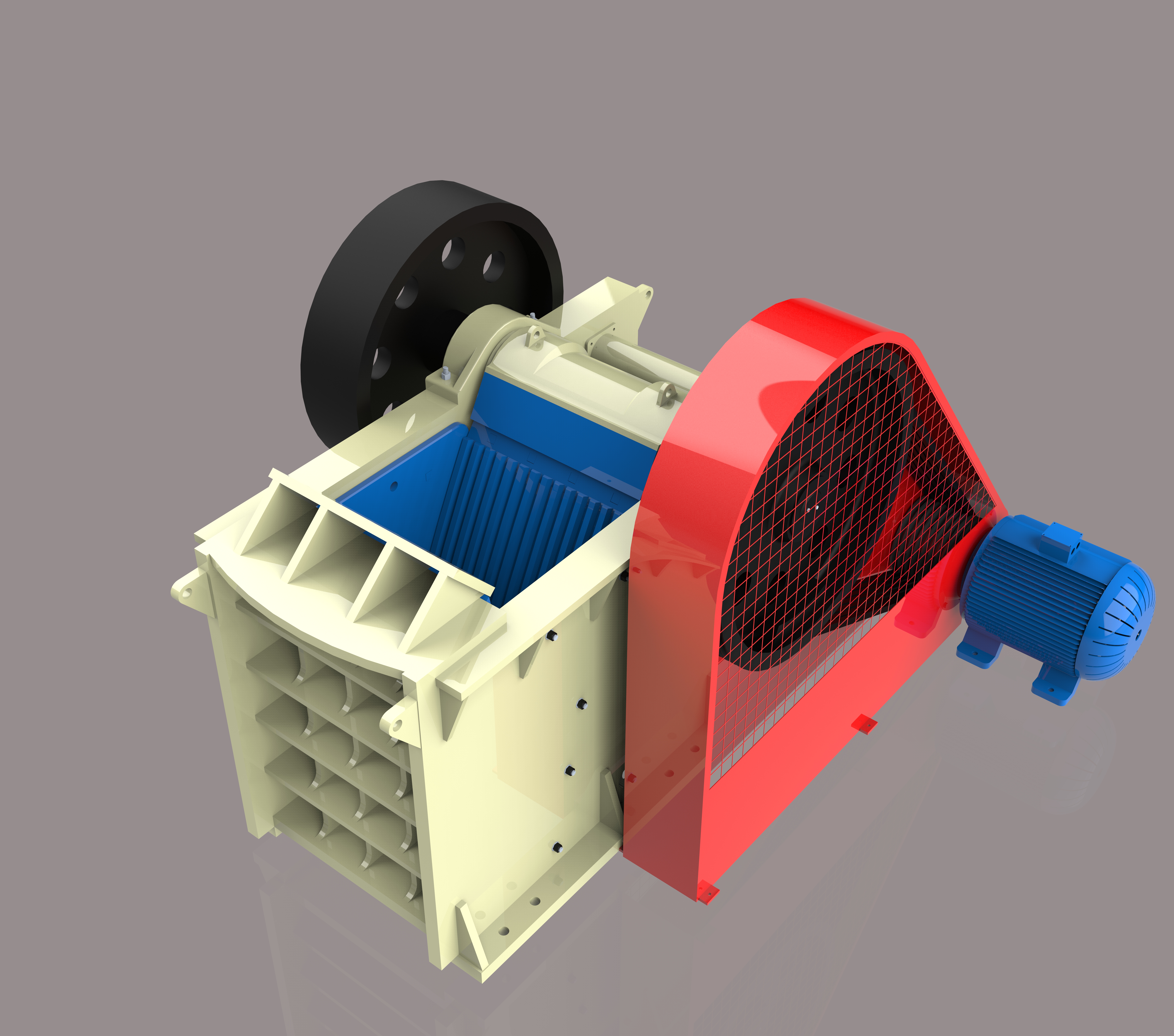

[Introduction]: Jaw Crusher The Jaw Crusher PE400×600 and PE500×750 have made the following improvements: ● Deep crushing chambe

● Product Overview

Jaw crusher crushes materials through the periodic movement of the moving jaw, with high production capacity, large crushing ratio, and high crushing efficiency. It is usually used in the coarse crushing stage.

Product working principle

Although there are various structural types of jaw crushers, their working principle is the same, which is to crush materials through the periodic movement of the moving jaw. During the process of swinging around the suspension axis towards the fixed jaw, the material located between the two jaw plates is subjected to a combination of crushing, splitting, and bending. At the beginning, the pressure is relatively low, causing the volume of the material to shrink and the materials to approach and squeeze each other tightly; When the pressure rises beyond the strength that the material can withstand, crushing occurs. On the contrary, when the movable jaw swings away from the fixed jaw in the opposite direction, the material moves downward by its own weight. Each periodic movement of the moving jaw causes the material to undergo a crushing action and be pushed downwards for a certain distance. After several cycles, the crushed material is discharged from the discharge port outside the machine.

● Product advantages

The connection between the large belt pulley and counterweight wheel of a larger jaw crusher and the main shaft adopts a tensioning sleeve form, making it easy to replace the bearings.

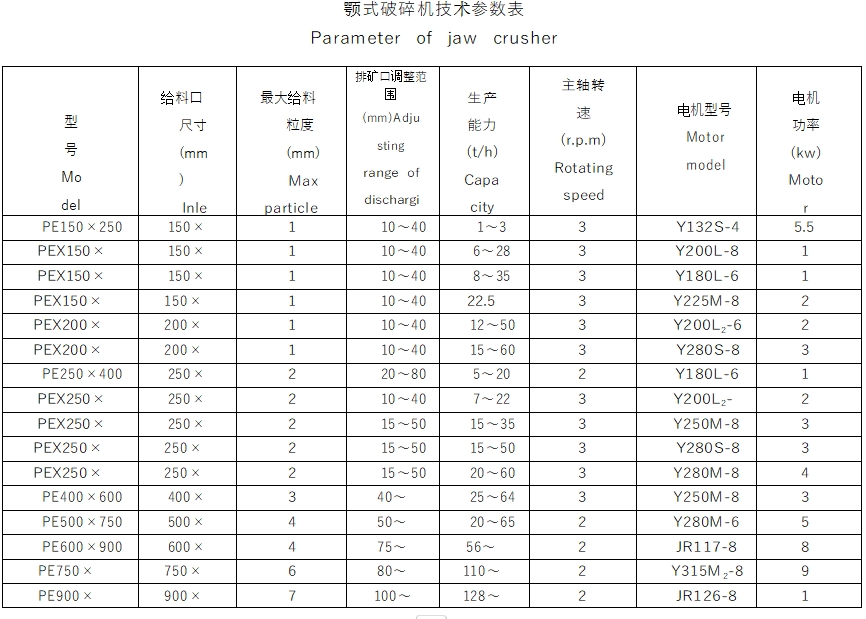

● Product parameters

A medium and fine crushing machine, where the spring serves both as a safety device and affects the