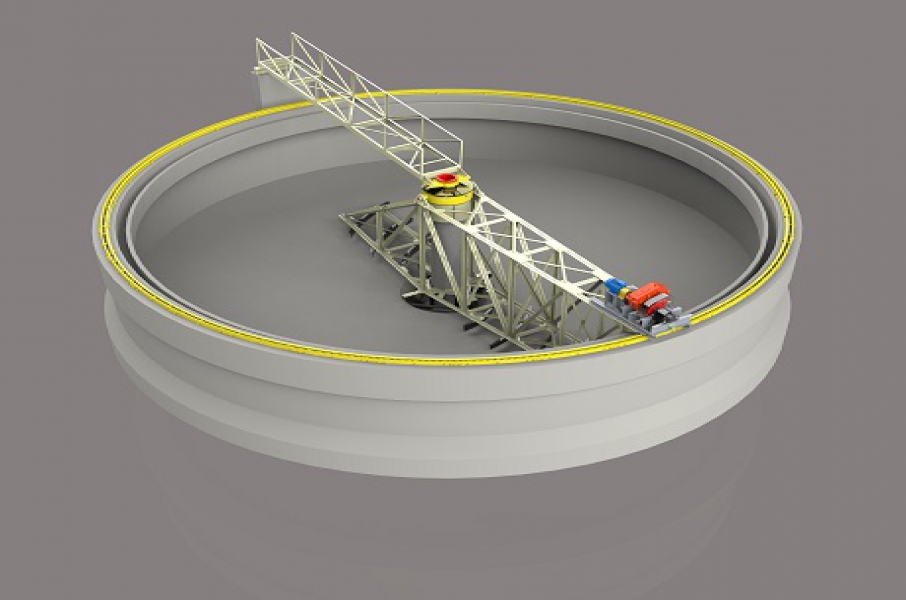

[Introduction]: Peripheral Rack Drive Thickener The peripheral drive thickener is mainly used for de-watering treatment of concentrates and tailings

● Product Overview

The peripheral transmission concentrator is mainly used for dewatering of concentrate and tailings in mineral processing plants, and can also be used for dewatering, desliming, and sewage treatment in light chemical industries and coal preparation plants.

[Applicable materials] Concentrate concentrate and dehydrate tailings, concentrate and clarify clean coal and tailings slurry

【 Scope of Application 】 Concentration and purification of solid slurry in industries such as chemical, coal, building materials, water sources, and sewage treatment

● Working principle of the product

The concentration tank is made of reinforced concrete or pure steel shell, with a reinforced concrete pillar or steel pillar at the center. One end of the moving beam and the current collector are placed on the central pillar of the concentration tank. The transmission mechanism is located at the other end of the moving beam and consists of a motor, coupling, reducer, gear, rack, and other components. The power supply is connected to the collection device on the central pillar, and the current is introduced into the motor through the cable laid on the rake frame. Through the movement of the transmission mechanism, the moving beam is driven to rotate. The scraper installed on the moving beam scrapes and collects the sediment, and the concentrated material is output through the lower foundation conduit.

● Product advantages

1. Add a degassing tank to eliminate solid particles from adhering to bubbles,

2. Add a buffer box on the central bracket to prevent the ore from being fed too quickly and causing overflow,

3. The old structure of the center bracket is a self-made sand frame bearing, which has been replaced with a rotary support. The structure is compact, with good sealing performance. The steel ball contacts the circular arc raceway at four points, and can simultaneously withstand axial force, radial force, and overturning torque. It is easier to maintain, easy to refuel, and has an extended practical life.

4. Move the ore vertical tube downwards to ensure that the slurry falls evenly and steadily, effectively preventing the phenomenon of tipping caused by residual pressure on the ore.

5. Add a flocculant addition device at the mining pipeline to increase processing capacity by 3-6 times.

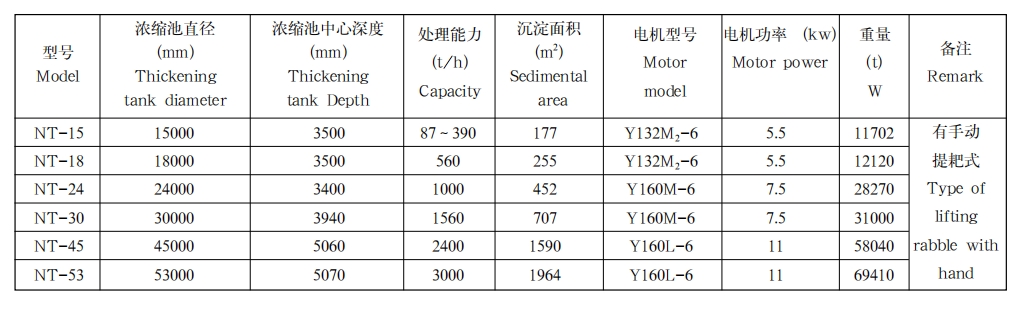

● Product parameters

The peripheral roll drive thickener is a peripheral drive thickener with the longest possible diamet