[Introduction]: High-Efficiency Thickener (Patented Product) The high-efficiency thickener has adopted new technological structures in flocculant addition, feed

● Product Overview

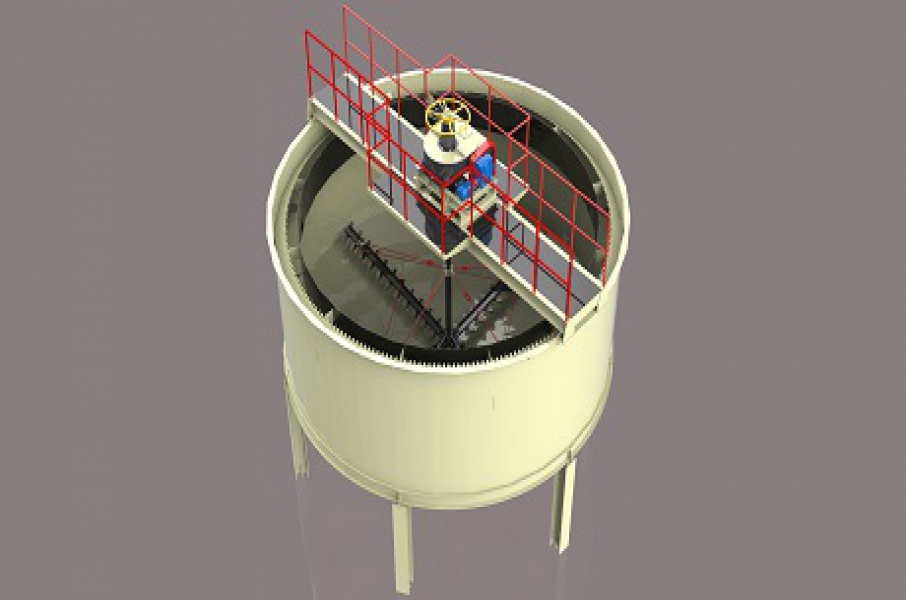

The high-efficiency thickener adopts new technological structures in terms of flocculant addition, ore feeding method, automation control, and internal structure. Compared with ordinary thickeners, high-efficiency thickeners have higher production capacity (processing capacity can be increased by several times or tens of times), lower traditional power, compact structure, and smaller footprint.

[Applicable materials] Coal materials, mineral mud, wastewater, waste residue, etc

【 Scope of Application 】 It can be widely used in metallurgy, mining, coal, chemical industry, building materials, environmental protection and other departments

● Working principle of the product

The thickener utilizes the gravity of solid particles to automatically settle and obtain clear overflow and concentrated bottom flow, thereby achieving solid-liquid separation.

● Product advantages

1. Add a degassing tank to eliminate solid particles from adhering to bubbles, similar to a "parachute" for settling. The ore feeding pipe is located below the liquid level to prevent gas from entering during ore feeding

2. The feeding sleeve moves downwards without a receiving tray, allowing the fed slurry to fall evenly and smoothly, effectively preventing the phenomenon of flipping caused by residual pressure on the ore

3. Adding an internal overflow weir allows materials to flow according to the specified path, preventing "short circuits" and significantly increasing the settlement zone

4. Change the overflow weir to a serrated shape to improve the local suction phenomenon caused by the unevenness of the overflow weir

5. Change the rake teeth from a diagonal line type to a curved line type to increase the concentration of the ore discharge bottom flow, thereby increasing the processing capacity

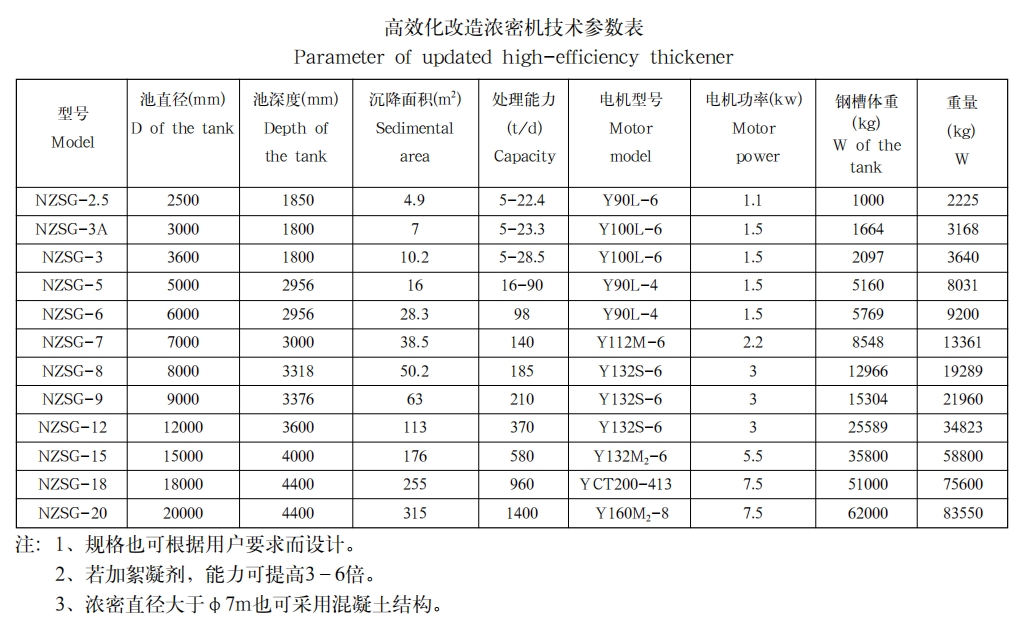

● Product parameters

The central drive high-efficiency thickener is mainly used for de-watering treatment of concentrates