[Introduction]: Dry Grate Ball Mill Dry ball mill is a key equipment for crushing materials after they have been crushed. It is widely u

● Product Overview

Dry ball mill is a key equipment for crushing materials after they have been crushed. It is widely used in the production industries of cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal beneficiation, and glass ceramics.

【 Scope of application 】 Production industries such as cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal beneficiation, and glass ceramics, dry grinding

Production capacity: 0.62-180t/h

● Working principle of the product

Dry ball mill is a horizontal cylindrical rotating single or double chamber device. The working principle of the ball mill with dual compartments is external gear transmission, with two compartments. The material is uniformly fed into the first compartment of the mill through the feeding device and the hollow shaft screw. The compartment is equipped with stepped or corrugated lining plates and contains steel balls of different specifications. The rotation of the cylinder generates centrifugal force, which brings the steel balls to a certain height and then drops them, causing heavy impact and grinding on the material. After the material reaches rough grinding in the first warehouse, it enters the second warehouse through a single-layer partition plate. The warehouse is lined with a flat lining plate and contains steel balls for further grinding of the material. The powdered material is discharged through the discharge grate to complete the grinding operation.

● Product advantages

Dry ball mill technology can not only produce by dry method but also by wet method, and can perform grinding and drying operations simultaneously.

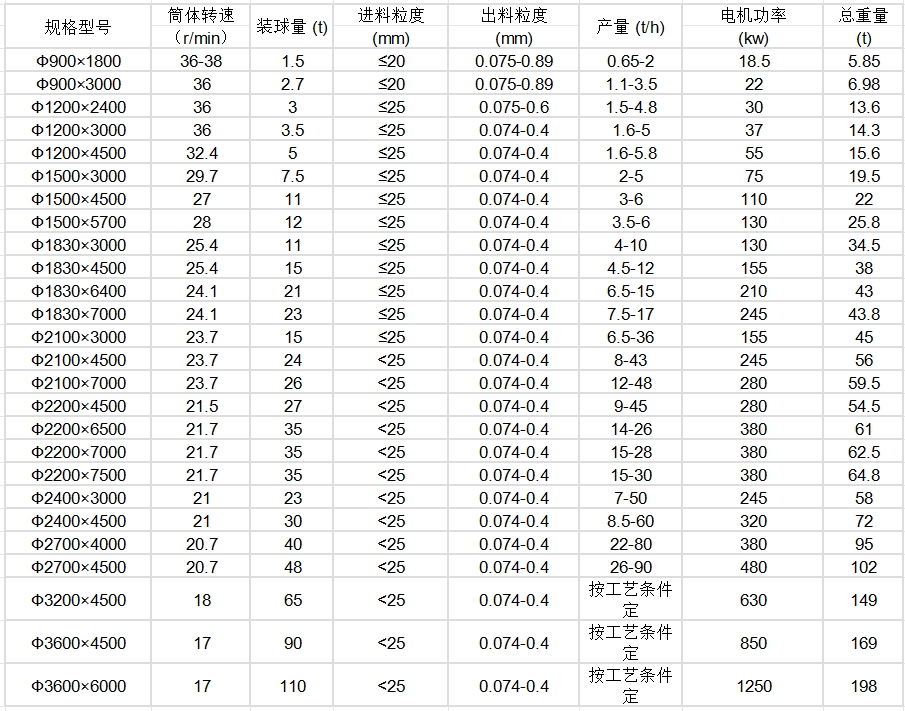

● Product parameters

A grinding mill that uses steel rods as grinding media. The rod mill comes in three types: overflow