[Introduction]: Straight Tube Rolling Bearing Energy-Saving Overflow Ball Mill ● The transmission uses large double-row self-aligning roller bearings instead of sliding bearings,

●Product Overview

The overflow ball mill is a wet grinding device, named for its overflow discharge. It is commonly used in various ore dressing plants, often for the final stage of fine grinding. Since the overflow ball mill has a cylindrical shape, it is often differentiated into short and long cylinders based on the length of the cylinder. However, their structure and working principles are the same.

●Working Principle of the Product

During operation, the cylinder rotates uniformly around the horizontal axis. The material is fed into the cylinder through the hollow shaft by the feeding device. Together with the steel balls, the material deviates and rises to a certain height under the combined action of centrifugal force and the friction of the cylinder lining. Then, it falls in a parabolic trajectory due to its own weight. In this way, the material is continuously broken and fractured by colliding and impacting with the steel balls. The discharge of the overflow ball mill is non-forced. Since the hollow shaft diameter at the discharge end is slightly larger than that at the feed end, the pulp surface inside the mill is inclined towards the discharge end. When the pulp surface height exceeds the lower generatrix of the discharge port, the pulp overflows and is discharged from the mill.

●Product Advantages

1. The structure is simple, and maintenance is convenient. Since the discharge pipe is cast with reverse threads, large ore chunks and steel balls are not easily discharged outside the machine.

2. The hollow shaft is made of cast steel, with replaceable liners. The large rotating gear is processed by casting and hobbing. The cylinder is lined with wear-resistant liners, providing excellent wear resistance.

3. The starting current is low, the starting time is short, and the operation is flexible. The normal working current is reduced by 20%-30% compared to ordinary mills, achieving the goal of energy saving.

4. The investment cost is low, and fewer auxiliary devices are required. The material transportation device is simple, effectively controlling the ore dressing cost.

5. The automation control level of the mill is improved, using PLC control with functions such as audio-visual alarms and fault diagnosis, achieving integrated control of mechanical, electrical, and hydraulic systems.

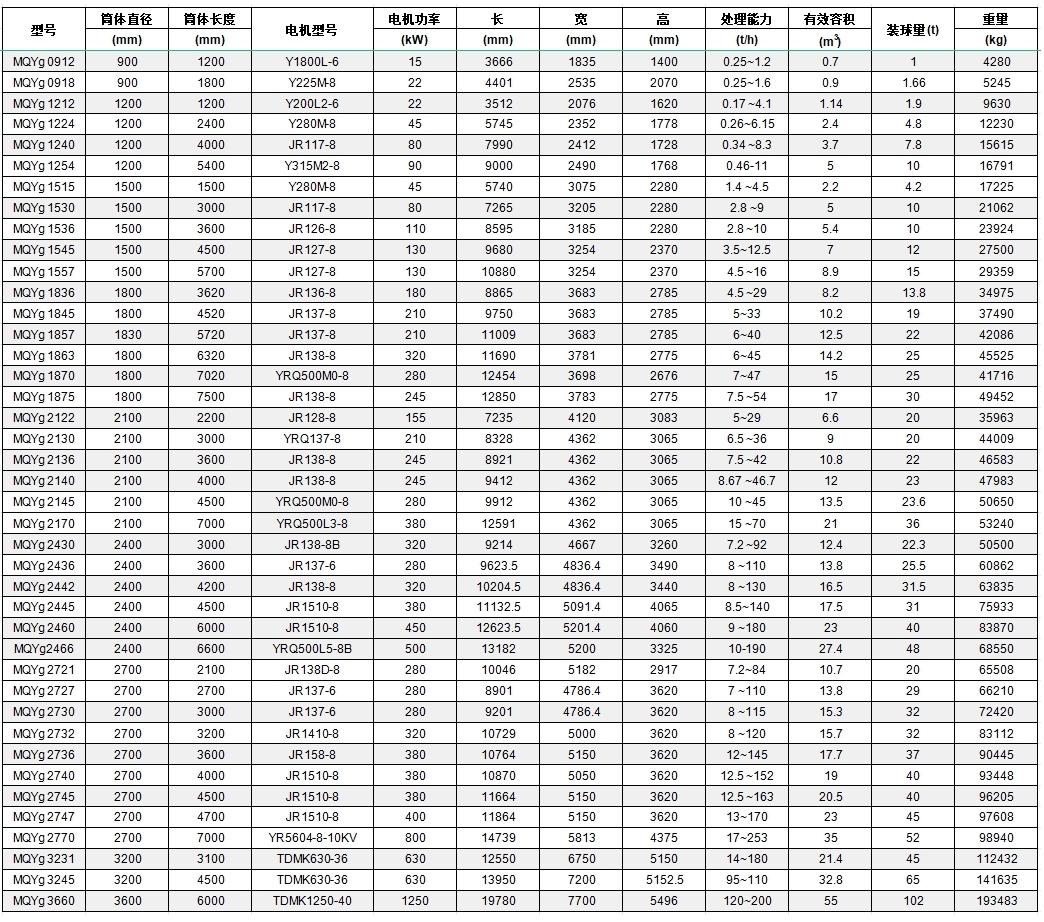

●Product Parameters

The grate ball mill is a key device for crushing materials after they have been broken. It is widely

● The transmission uses large double-row self-aligning roller bearings instead of sliding bearings,