[Introduction]: Wet Grate Ball Mill The wet grate ball mill is a traditional ball mill that uses a discharge grate for forced ore discha

● Product Overview

Wet grid ball mill is a traditional ball mill that relies on the forced discharge of ore grids. If multi-stage grinding is used, it is generally used for one-stage grinding. Its cylinder body uses high wear-resistant lining plate, which has good wear resistance, long service life, and easy maintenance.

【 Scope of Application 】 Metallurgical, mining, building materials, chemical and other industries

Effective volume: 0.45-87m ³

● Product Structure

● Working principle of the product

The motor drives the grinder cylinder to rotate at an appropriate speed through the transmission and reduction of gear pairs. The grinding medium placed inside the cylinder is lifted to a certain height under the action of centrifugal force, friction force, and gravity, and then falls in a throwing or falling state. The material inside the cylinder is crushed by the impact of the medium. At the same time, due to the rolling or sliding of the medium, the material is ground by the grinding and peeling effect. The ground material is discharged through the discharge port. According to the needs, the grinder can be equipped with air clutch, slow drive device, lifting device, spray lubrication device, etc. The main bearing of the ball mill can be equipped with ordinary sliding bearings, dynamic and static pressure bearings, static pressure bearings, and rolling bearings as needed.

● Product advantages

1. The large ball mill is equipped with a lifting device for easy maintenance;

2. Large ball mills with slow transmission for easy maintenance and start-up;

3. The large ball mill adopts oil mist lubrication for the large and small gears to ensure reliable lubrication, extend the service life of the large and small gears, and save lubricating oil;

4. The large ball mill is equipped with an air clutch and adopts flexible starting to reduce the significant impact on the power grid of the selection plant during the start-up of the ball mill.

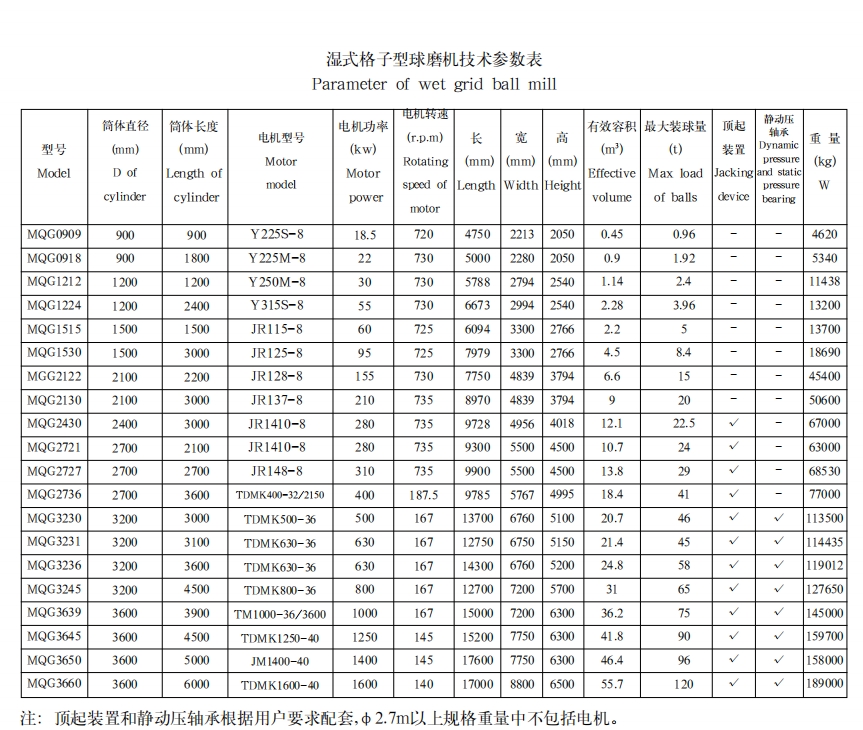

● Product parameters

● The transmission uses large double-row self-aligning roller bearings instead of sliding bearings,

● Jacking device for easy maintenance ● Hydrostatic and hydrodynamic bearings for stable and reliabl