[Introduction]: Wet Rod Mill A grinding mill that uses steel rods as grinding media. The rod mill comes in three types: overflow

● Product Overview

A grinding equipment that uses steel bars as the grinding medium. There are three types of rod mills: overflow type rod mill, end peripheral discharge rod mill, and center peripheral discharge rod mill, which can meet the different needs of customers.

【 Scope of Application 】 Mainly used for rough grinding operations

Production capacity: 0.62-250t/h

● Product Structure

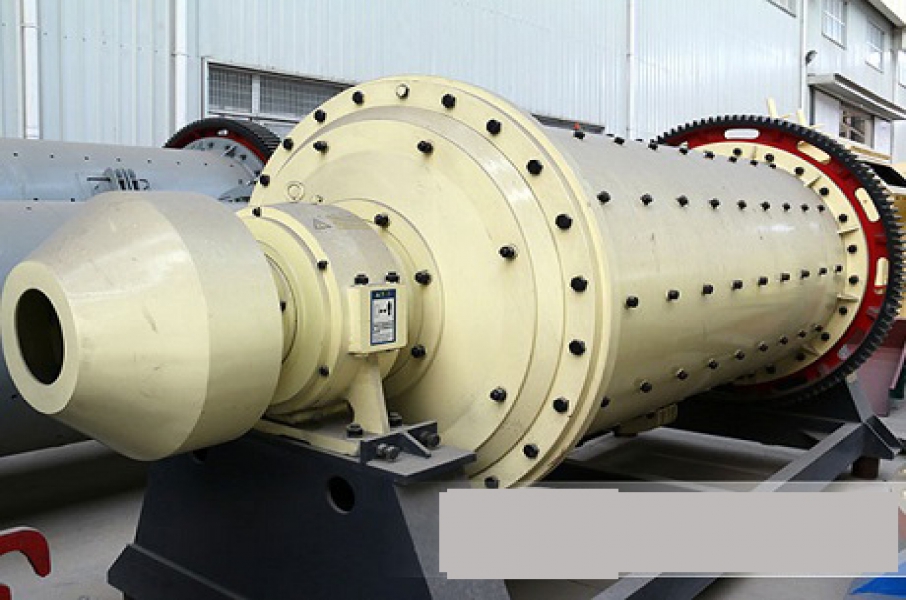

The ball mill is mainly composed of a feeding section, a feeding section, a main bearing section, a cylinder section, a transmission section, a discharge section, and a main motor.

There are three types of rod mills: overflow type rod mill, end peripheral discharge rod mill, and center peripheral discharge rod mill, which can meet the different needs of customers.

● Working principle of the product

The rod mill is driven to rotate by a motor through a reducer and peripheral large gears, or by a low-speed synchronous motor directly through peripheral large gears. The cylinder is equipped with a suitable grinding medium - steel rod. Under the action of centrifugal force and frictional force, the grinding medium is lifted to a certain height and falls in a throwing or releasing state. The ground material continuously enters the interior of the cylinder through the feeding port, is crushed by the moving grinding medium, and is discharged from the machine through overflow and continuous feeding force for the next process operation.

● Product advantages

The conical end cap of the rod mill has a small curvature, which allows the steel rod to move regularly inside the mill;

2. The diameter of the hollow shaft for ore discharge is relatively large, which is convenient for maintenance and can also lower the slurry level for rapid ore discharge;

3. The product has uniform particle size and less over crushing phenomenon.

● Product parameters

● Jacking device for easy maintenance ● Hydrostatic and hydrodynamic bearings for stable and reliabl

Dry ball mill is a key equipment for crushing materials after they have been crushed. It is widely u