[Introduction]: High-Efficiency Pulse Dust Collector The MDC series pulse dust collector overcomes the shortcomings of insufficient cleaning strength in

● Product Overview

The MDC series pulse dust collector overcomes the shortcomings of insufficient anti blowing cleaning intensity and general pulse cleaning dust reattachment, improving cleaning efficiency and greatly reducing spraying frequency. This type of dust collector uses a high-performance pulse valve to reduce the pressure of the injection air source. In this way, the equipment operates with low energy consumption, the lifespan of filter bags and pulse valves is extended, and the overall technical performance is greatly improved.

[Applicable Materials] Suitable for the purification of dusty gases and material recovery in metallurgy, building materials, cement, machinery, chemical, power, and light industry industries.

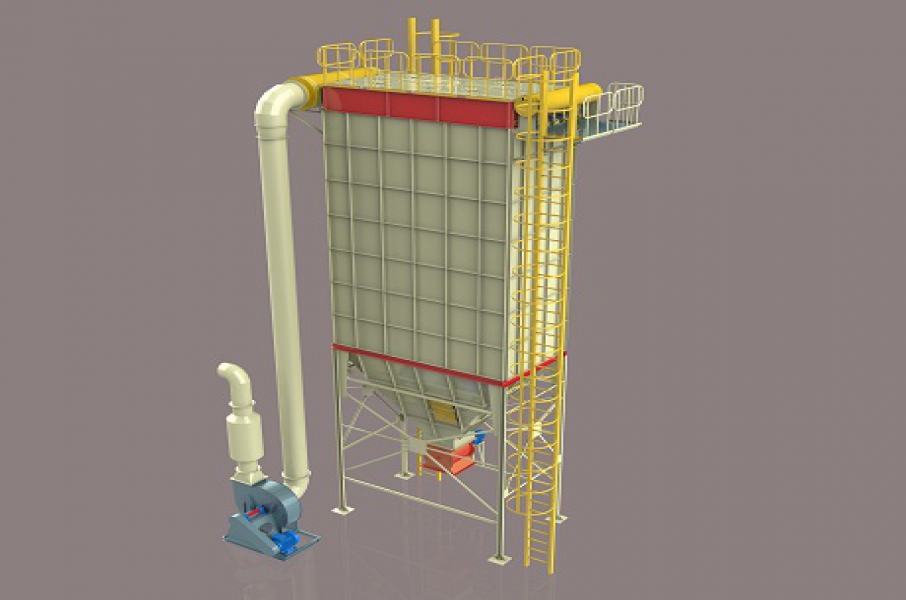

● Product Structure

● Working principle of the product

Dust collector refers to the method of removing dust attached to the filter medium (bag or filter cartridge) by blowing compressed air; Depending on the size of the dust collector, there may be several sets of pulse valves controlled by a pulse controller or PLC. Each set of pulse valves is opened to remove dust from the bag or filter cartridge it controls, while the other bags or filter cartridges work normally. After a period of time, the next set of pulse valves is opened to clean the next part of the dust collector, which consists of ash hopper, upper box, middle box, lower box, etc. The upper, middle, and lower boxes are divided into compartments. During operation, dusty gas enters the ash hopper through the air inlet duct. Coarse dust particles directly fall into the bottom of the ash hopper, while fine dust particles enter the middle and lower boxes upwards with the turning of the airflow. Dust accumulates on the outer surface of the filter bag, and the filtered gas enters the upper box to the clean gas collection pipe exhaust duct, and is discharged to the atmosphere through the exhaust fan. The dust cleaning process involves first cutting off the clean air outlet duct of the room, so that the bag in the room is in a state of no airflow passing through (stopping the air and cleaning the dust in each room). Then, the pulse valve is opened and compressed air is used for pulse blowing to clean the dust. The shut-off valve is closed for a sufficient time to ensure that the dust peeled off from the filter bag settles in the ash hopper after spraying, avoiding the phenomenon of dust adhering to the adjacent filter bag surface with the airflow after leaving the filter bag surface. The filter bag is thoroughly cleaned, and the exhaust valve, pulse valve, and ash discharge valve are fully automatically controlled by a programmable controller. The dusty gas enters through the air inlet, and when passing through the ash hopper, some large particles of dust in the gas are separated by inertia and gravity, and directly fall into the bottom of the ash hopper. The dusty gas enters the filter bag filtration area of the middle box after passing through the ash hopper. The gas passes through the filter bag, and the dust is trapped on the outer surface of the filter bag. The purified gas enters the upper box through the filter bag opening and is then discharged through the air outlet.

● Product advantages

1. High efficiency, no longer adsorbing dust

2. The spraying cycle can be extended by more than twice compared to general pulses

3. The pressure of the gas source has decreased from the conventional 0.5-0.7Mpa to 0.4-0.6Mpa

4. High service life of filter bags and pulse valves

5. The filter bag mouth adopts a spring tension structure, which is easy to disassemble and has good sealing performance

6. The ash cleaning system automatically controls ash cleaning, ash unloading, and over temperature alarm

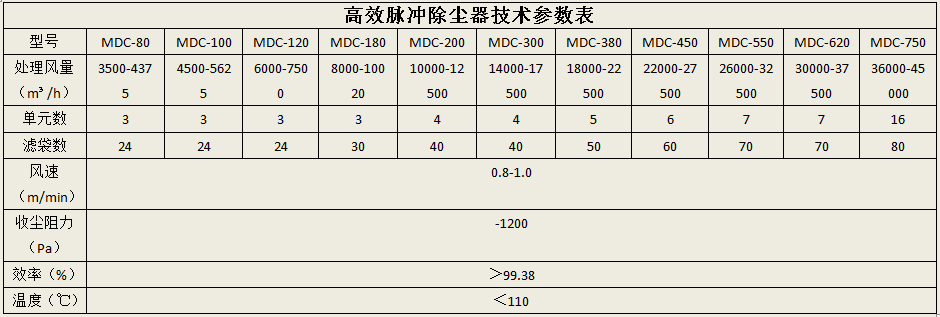

● Product parameters

The belt conveyor is widely used in metallurgy, coal, transportation, hydropower, and other departme