[Introduction]: High-Efficiency Circular Vibrating Screen The YA type circular vibrating screen adopts internationally advanced technologies and processes suc

● Product Overview

The YA type circular vibrating screen adopts internationally advanced processes and technologies such as ring groove rivets, eccentric shaft and eccentric block vibrators, low stress shock-absorbing springs, ultra heavy large clearance bearings, and thin oil lubrication. It has the advantages of high screen frame structure strength, reasonable mechanical structure, low operating temperature of large clearance bearings, low operating noise, and long service life.

● Product Structure

The circular vibrating screen is mainly composed of a screen box, screen mesh, vibrator, damping spring, bracket, electric motor, etc. The screen mesh is the main vulnerable component. According to the variety of materials and user requirements, high manganese steel woven mesh and polyurethane mesh can be used. The sieve plate is divided into single-layer, double-layer, and multi-layer, and there are light and heavy types; The electric motor can be installed on the left or right side.

● Working principle of the product

The vibrator is installed on the side plate of the screen box and is driven to rotate by an electric motor through a V-belt, generating centrifugal inertia force that forces the screen box to vibrate.

● Product advantages

1. Using low stress damping springs, the operating noise is low,

2. Adopting ultra heavy large oil gap bearings, with low operating temperature and long service life,

3. Adopting ring groove rivets and plate type screen box frame structure, the screen frame structure has high strength,

4. We can provide wear-resistant screens that can make materials stuck in the sieve holes jump out, preventing the sieve holes from clogging,

5. Large processing capacity, strong universality of components, easy maintenance,

6. Adding a receiving tray between the material throwing point and the screen surface during installation increases the screening area and efficiency, while reducing the impact of the material on the screen surface and increasing its service life,

7. It can be manufactured in multiple layers according to product requirements.

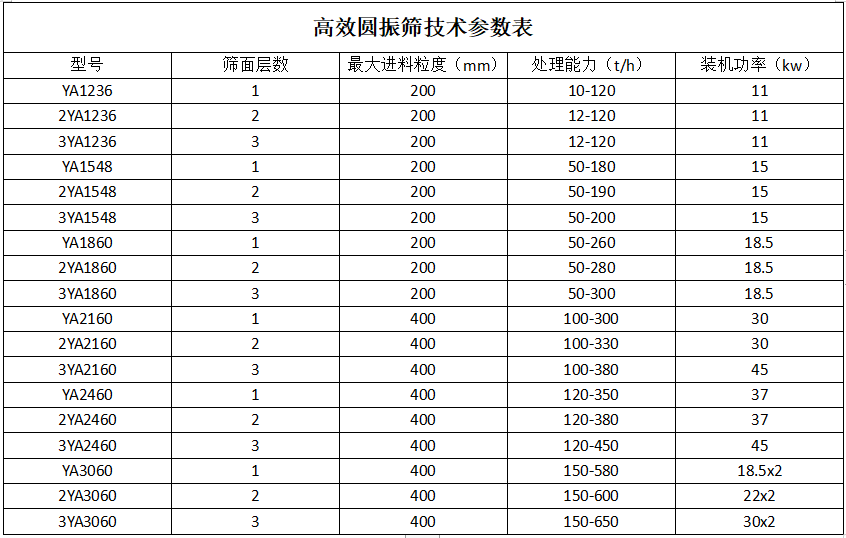

● Product parameters

The ZSW series vibrating feeder consists of a feeding trough, vibrator, spring support, and transmis

The belt conveyor is widely used in metallurgy, coal, transportation, hydropower, and other departme