[Introduction]: Belt Conveyor The belt conveyor is widely used in metallurgy, coal, transportation, hydropower, and other departme

● Product Overview

Belt conveyors are widely used in industries such as metallurgy, coal, transportation, and water and electricity to transport bulk materials or finished items due to their large conveying capacity, simple structure, easy maintenance, low cost, and strong versatility. According to the requirements of the conveying process, it can be conveyed by a single machine, or by multiple machines or combined with other conveyors to form a horizontal or inclined conveying system.

● Working principle of the product

The working environment temperature of a belt conveyor is generally between -10 ℃ and 40 ℃, and the material temperature is required to not exceed 75 ℃. The heat-resistant rubber belt can transport high-temperature materials below 120 ℃, and it is not suitable to use a belt conveyor when the material temperature is higher. At the same time, the loose density of the transported material should be 2.5t/m3. When transporting materials containing acidic, alkaline oil substances and organic solvents, it is necessary to use rubber or plastic belts that are resistant to oil and acid and alkali.

● Product advantages

1. Adopting wear-resistant multi-layer cloth adhesive wear-resistant tape, it is durable and long-lasting,

2. The roller adopts a rubber roller, which has light belt wear and a long service life,

3. Equipped with anti deviation wheels, the belt operates with high precision,

4. Equipped with an automatic tensioning device, the conveying capacity is stable and the belt wear is minimal.

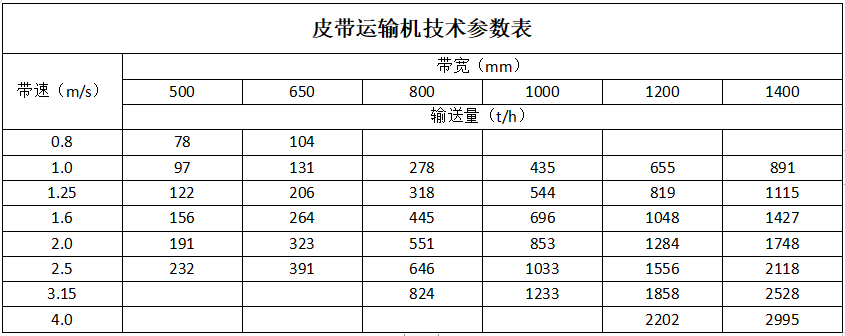

● Product parameters

The YA type circular vibrating screen adopts internationally advanced technologies and processes suc

The MDC series pulse dust collector overcomes the shortcomings of insufficient cleaning strength in