● Product Overview

The permanent magnet powder dry magnetic separator is a newly developed high-efficiency dry separation equipment that can be widely used in metallurgy and other industries. This device has the characteristics of turbulent magnetic field and high separation factor, advanced structure, light weight, reliable operation, and easy maintenance.

【 Scope of Application 】 The magnetic separator is suitable for wet magnetic separation of materials such as magnetite, pyrrhotite, roasted ore, and ilmenite with particle sizes below 3mm. It is also used for iron removal operations of coal, non-metallic minerals, building materials, and other materials

● Working principle of the product

The magnetic poles of the dry sorting machine are fixed, and the cylinder is rotating. The direction of rotation of the cylinder is indicated by the arrow on the cylinder and cannot be reversed.

The drum part of the dry magnetic separator is supported by rolling bearings, which are lubricated with calcium based oil and added every three months. The reducer is lubricated with mechanical oil, and the oil level should be controlled within the range of the oil level line. The oil should be replaced once a year.

It consists of a variable speed transmission device and a frame. Its working principle is that when the processed mineral material passes through the magnetic field of the magnetic separator, under the action of magnetic and mechanical forces, minerals with different magnetic properties move along different paths, thereby achieving the separation of magnetic and non-magnetic substances in the mineral material.

● Product advantages

1. Used for pre selection of low-grade ores with high enrichment ratio, which can significantly improve the grinding grade

2. Used for purifying iron concentrate, removing associated bodies and gangue

3. Used for tailings reselection

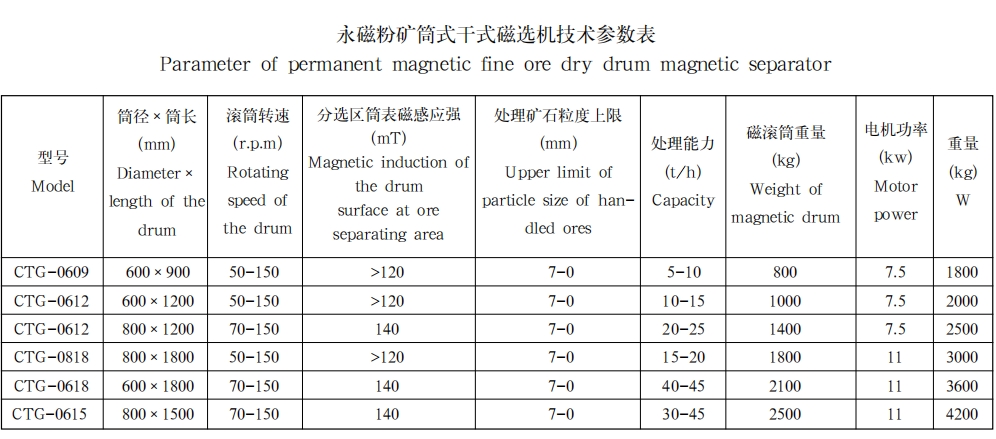

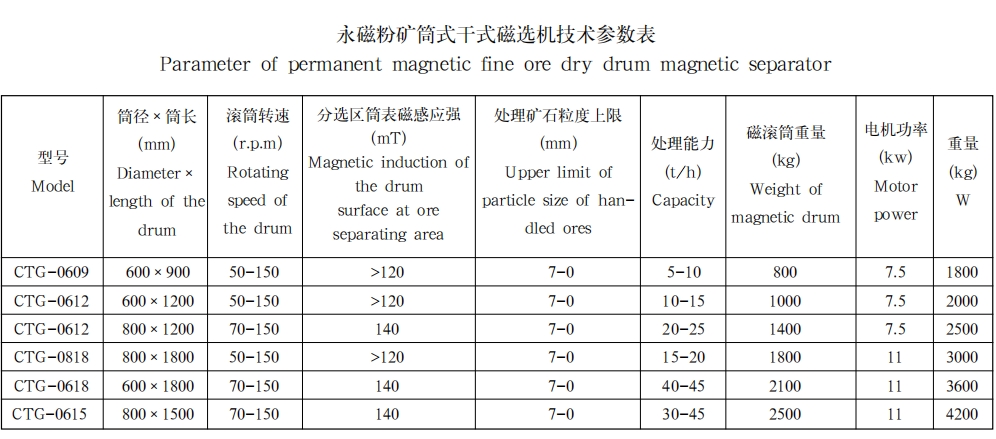

● Product parameters

0535-6350765

0535-6350765