● Product Overview

A wet permanent magnet magnetic separation equipment commonly used for selecting strong magnetic minerals.

【 Scope of Application 】 The permanent magnet drum magnetic separator can be used for pre selection, coarse selection, selection, etc., with a selected particle size range of 2-10mm.

[Processing capacity] 24t/h-240t/h

[Product Performance] High performance, high coercivity, high remanence, and neodymium iron boron materials are selected for magnetic materials, with a large depth of action; The surface of the cylinder can be lined with wear-resistant rubber.

● Working principle of the product

Permanent magnet drum magnetic separators can be divided into three types based on their bottom structure: co current type, counter current type, and semi counter current type.

Downstream type permanent magnet drum magnetic separator: The direction of slurry feeding is the same as the direction of drum rotation, the concentrate is discharged on the other side, and the tailings are directly discharged at the bottom. It is generally used for coarse and fine selection of 6-0mm strong magnetic minerals, with low recovery rate and high grade, but it is not suitable for processing fine-grained materials.

Reverse flow permanent magnet drum magnetic separator: The direction of slurry feeding is opposite to the direction of drum rotation, and the concentrate is discharged on the feeding side, while the tailings are discharged on the other side. It is generally used for coarse and sweeping selection of 0.6-0.0mm strong magnetic ores, with high recovery rate (due to the distance between the tailings discharge point and the ore feeding port, the selection is sufficient) but low grade.

Half counter current type permanent magnet drum: The direction of slurry feeding is half the same as the rotation direction of the drum, while the other half is opposite. The difference from the co current type is that the slurry rotates around in the tank. Because the slurry is washed into a loose state by the dispersed water, it can prevent inclusions, and the direction of slurry movement is consistent with the direction of magnetic force, which is conducive to the recovery of 0.5-0mm strong magnetic ores. Due to the high recovery rate and grade of coarse, fine, and sweeping, the slurry surface is stable, resulting in stable separation. Therefore, it is widely used.

● Product advantages

1. The magnetic system adopts neodymium iron boron magnets with high magnetic energy product and high coercivity, with high magnetic field strength and an 8-year demagnetization rate not exceeding 5%;

2. A large angle magnetic system with gradually changing field strength and smooth transition, increasing the length of the sorting zone and the number of magnetic flips, achieving efficient separation of magnetic minerals and non (weak) magnetic minerals;

3. The magnetic system is wrapped in non-magnetic stainless steel to ensure that the magnet does not come off;

4. According to different purposes and sorting conditions, each series of magnetic separators has different magnetic system designs and tank structures;

5. The cylinder is made of non-magnetic stainless steel and coated with wear-resistant rubber, significantly improving its service life;

6. The permanent magnet drum has strong adaptability to production and can withstand large fluctuations in ore feeding quantity, ore feeding particle size, and slurry concentration;

7. It can achieve superior beneficiation indicators of high grade and high recovery rate simultaneously;

8. Each series of magnetic separators can be used in combination or separately, and both can achieve excellent mineral processing indicators;

9. The tank structure is a semi countercurrent type, and can also be made into a downstream type tank according to sorting conditions and user requirements.

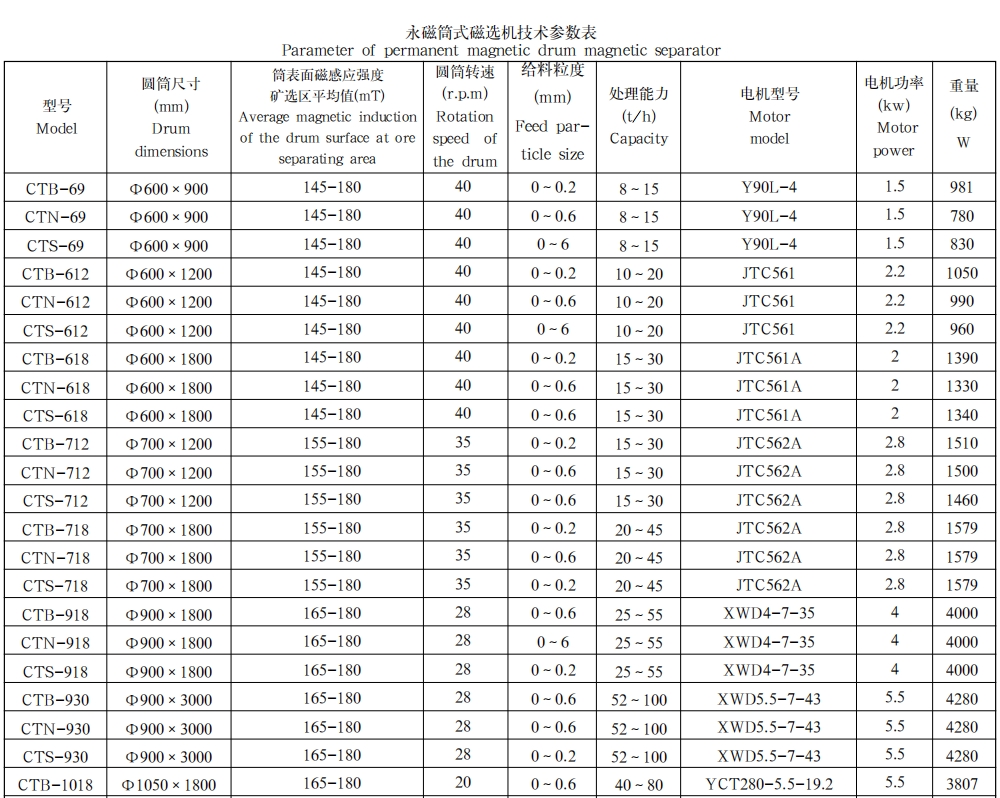

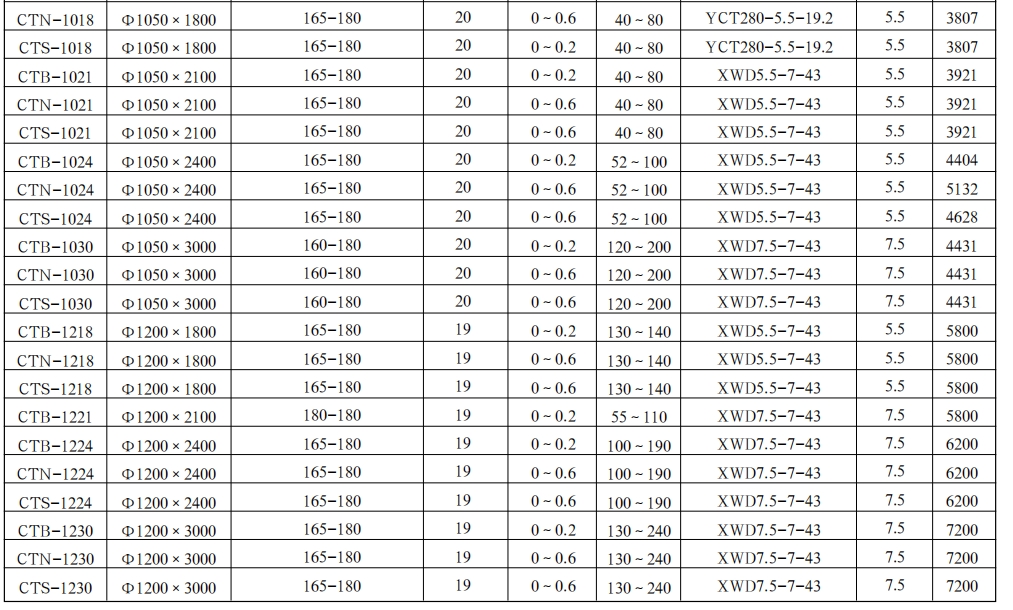

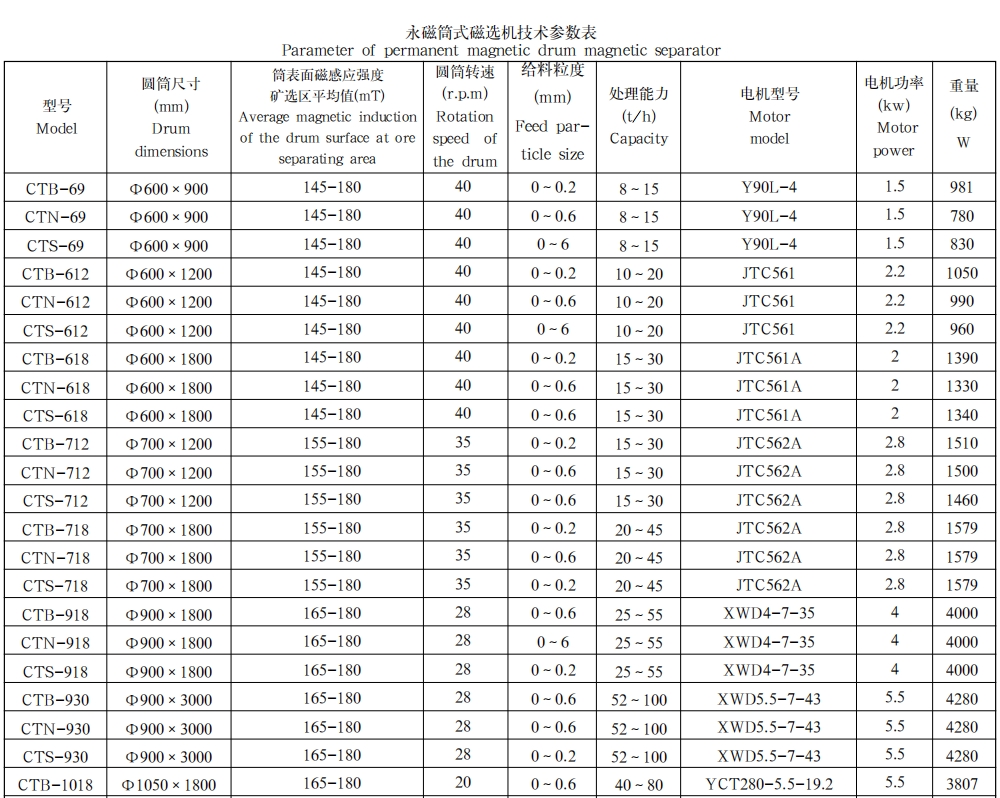

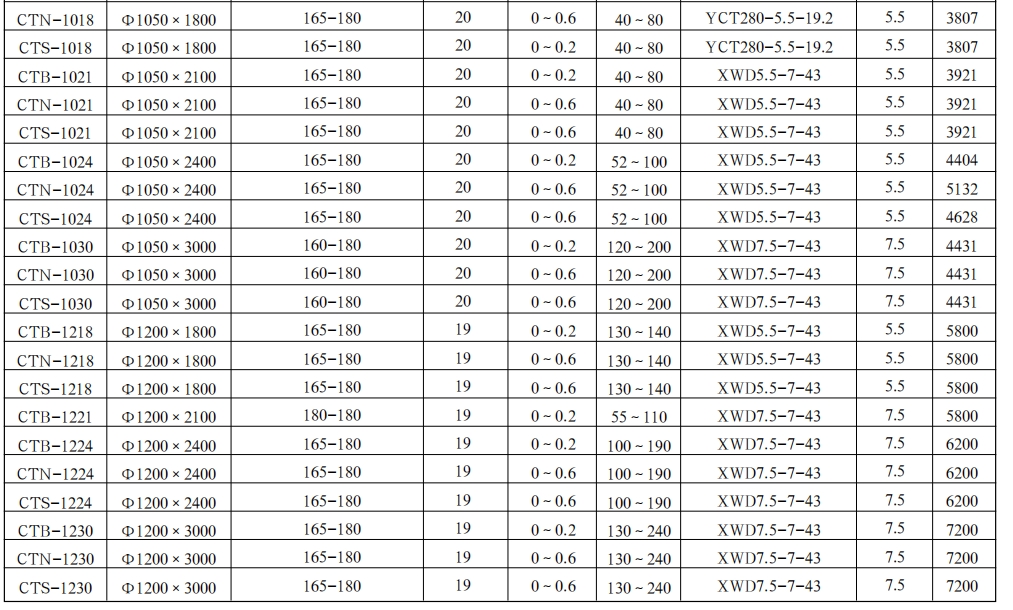

● Product parameters

0535-6350765

0535-6350765