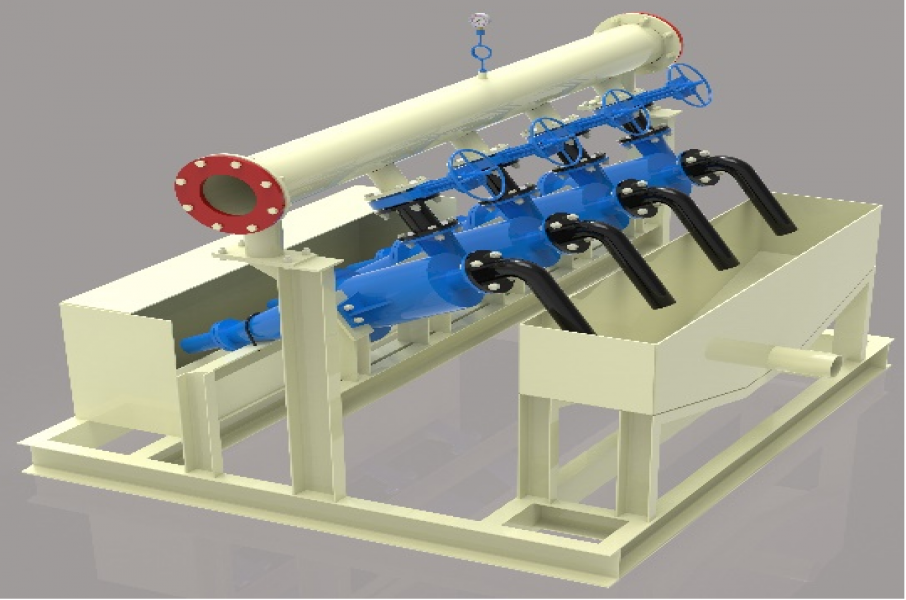

[Introduction]: High-Efficiency Concentrating Hydrocyclone The hydrocyclone group can meet the ore requirements of large mines. Our company can customize hydro

● Product Overview

The cyclone group can meet the ore demand of large mines. Our company can customize cyclone groups for users, select and determine the number of cyclones according to different feed particle sizes, bottom flow concentrations, and production volumes. Its classification efficiency is 20-30% higher than that of spiral classifiers, and can reach 70-85%.

● Working principle of the product

A cyclone is a device that utilizes fluid pressure to generate rotational motion. When the slurry enters the cyclone at a certain speed and encounters the cyclone wall, it is forced to rotate. Due to different centrifugal forces, the solid coarse particles in the slurry experience greater centrifugal forces and can overcome hydraulic resistance to move towards the wall. Under the combined action of their own gravity, they spiral downwards along the wall. Fine and small particles, as well as most of the water, experience less centrifugal force and rotate with the slurry before approaching the wall. Under the push of subsequent feeding, the slurry continues to move downwards and rotate, so coarse particles continue to concentrate towards the periphery, while fine particles stay in the central area. The particle size increases from the center towards the wall, forming a layered arrangement. As the slurry flows from the column part of the cyclone to the cone part, the flow cross-section becomes smaller and smaller. Under the contraction and compression of the outer slurry, the inner slurry containing a large number of small particles has to change its surface direction and move upward, forming an inner vortex. It is discharged from the overflow pipe and becomes an overflow, while the coarse particles continue to move downward along the wall of the cyclone, forming an outer vortex, and finally discharged from the bottom outlet, becoming sediment.

The combination of cyclone group and other equipment into a classification equipment group can increase the processing capacity of the mill by more than 15%. One of the combination devices, the multifunctional screen, can automatically return the coarse particles in the overflow to the mill.

● Product advantages

1. This cyclone is a new generation of high-efficiency classification and concentration cyclone developed and produced by our company based on the digestion and absorption of Malaysian cyclone classification technology. It aims to recover large particle materials as much as possible and increase the bottom flow concentration to form an auxiliary filtration layer on the dewatering screen surface.

2. The feeding port adopts a three-dimensional spiral feeding method, with low pressure, large processing capacity, smooth fluid operation, reduced turbulence during feeding, smooth fluid operation, and reduced wear on the feeding box during feeding.

3. The insertion depth of the overflow pipe of the traditional cyclone separator is appropriately extended to fully reduce the impurities of fine-grained materials in the settling sand.

4. Adopting a multi-stage variable cone design with different diameter cone ratios and angle cone ratios, to ensure the maximum tangential velocity of the slurry in the cyclone, reduce capacity loss, and achieve the best grading and concentration effect.

5. The use of molded high wear-resistant rubber material results in a service life that is 6 times longer than that of silicon carbide and 15 times longer than that of ordinary rubber.

● Product parameters

This de-watering screen is developed based on Malaysian technology and combined with our company's y