[Introduction]: High-Efficiency High-Frequency De-watering Screen This de-watering screen is developed based on Malaysian technology and combined with our company's y

● Product Overview

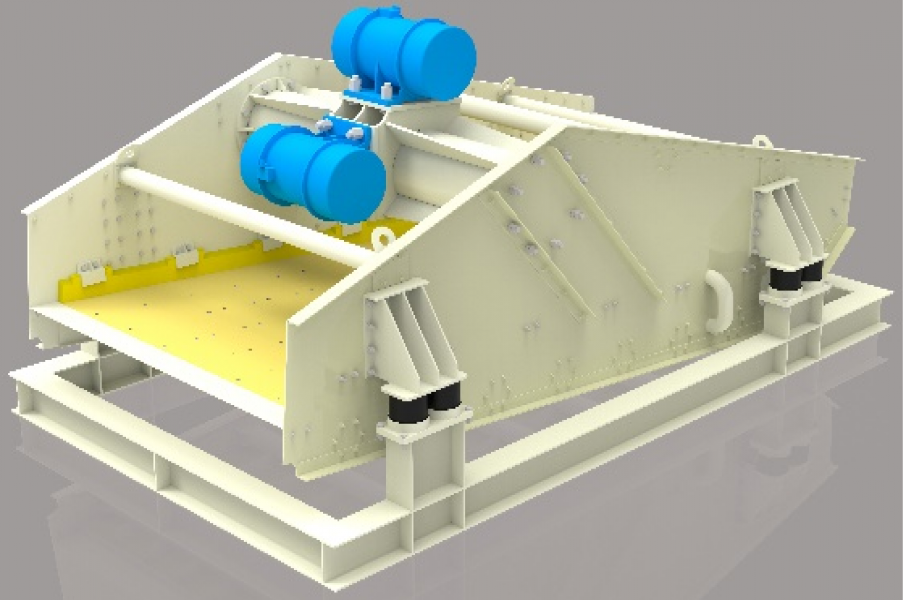

A uniquely designed multi frequency dewatering screen with high processing capacity and sufficient dewatering.

● Product advantages

1. This dehydration screen is manufactured based on the introduction of Malaysian technology and combined with our company's years of production experience. Mainly used for dry screening, wet screening, dehydration, desilting, and other processes of fine-grained materials in the sand and gravel aggregate industry, especially suitable for the recovery of fine sand in the mechanism sand industry. The motion trajectory of the high-frequency vibration dewatering screen is a straight line, with high processing capacity and good dewatering and recommendation effects;

2. The dehydration screen adopts a universal block eccentric and adjustable amplitude vibrator with dual electrode self synchronization technology. Drive two unrelated vibrators to operate synchronously in opposite directions, and the centrifugal force generated by the two sets of eccentric masses is superimposed along the vibration direction. The reverse centrifugal force cancels out, forming a single excitation vibration along the vibration direction, causing the sieve box to move back and forth in a straight line;

3. This series of dewatering screens is arranged according to the principle of equal thickness screening. Depending on the different materials on site, the excitation direction angle and screen surface can be adjusted accordingly to achieve the best combination of processing capacity and screening efficiency. The screen uses an electric motor to drive the exciter to rotate in reverse self synchronization, causing the screen body to produce linear motion;

4. The screen frame side plate is made of high-quality steel in one piece, and the side plate is connected to the crossbeam and exciter base with high-strength bolts or ring groove rivets, making the structure sturdy and reliable;

5. The screening surface is made of polyurethane material and is laid in sections on the lower discharge beam, making disassembly and assembly very convenient; Compared with conventional metal plates, the wear resistance is more than 5 times that of general rigid materials, and it is not easy to loosen or block. Simultaneously adopting a progressive screening method ensures the recovery rate of fine sand while reducing its moisture content.

● Product parameters

The hydrocyclone group can meet the ore requirements of large mines. Our company can customize hydro