[Introduction]: Spiral Classifier The spiral classifier is mainly used as an auxiliary device for grinding mills for pre-grading and i

● Product Overview

The high weir spiral classifier is mainly used as an auxiliary equipment for pre grading and inspection grading in grinding, and sometimes also used for washing clay containing ores and desliming and dehydrating slurry.

● Working principle of the product

The high weir spiral classifier uses a feed inlet located in the middle of the settling zone to feed the finely ground slurry into a water tank. Below the inclined water tank is the slurry grading settling zone, and the spiral rotates at low speed to stir the slurry, causing fine particles to suspend and overflow at the overflow weir. Coarse particles settle to the bottom of the tank and are transported by a screw to the discharge port as return sand for discharge. The position of the overflow weir is higher than the bearing center at the lower end of the spiral shaft and lower than the upper edge of the overflow end spiral. An automatic lifting device for sand return has been added to the sand return end, which eliminates the need for a large spoon head in the ball mill and ensures smoother operation of the ball mill.

● Product advantages

1. The equipment motors, reducers, and bearings are made of high-quality branded products (Weihai Huali/Zibo General/Harbin Axle).

2. The large tube shaft of the large-scale classifier is made of thick manganese steel plate rolled in one go without circumferential welds, greatly improving the strength of the tube shaft.

3. The overflow end of the main shaft adopts nylon bearings, which not only reduces costs and prolongs the service life, but also facilitates maintenance and replacement.

4. The blades are cut automatically, which is neat and beautiful.

5. The single spiral high weir classifier has added an automatic sand return lifting device at the sand return end, which automatically flows into the feed inlet of the ball mill. The ball mill feeder eliminates the configuration of the large spoon head, thereby reducing the uneven impact on the large and small gears, and generally saving 1-1.5 degrees per ton of ore, avoiding frequent maintenance of the large spoon head.

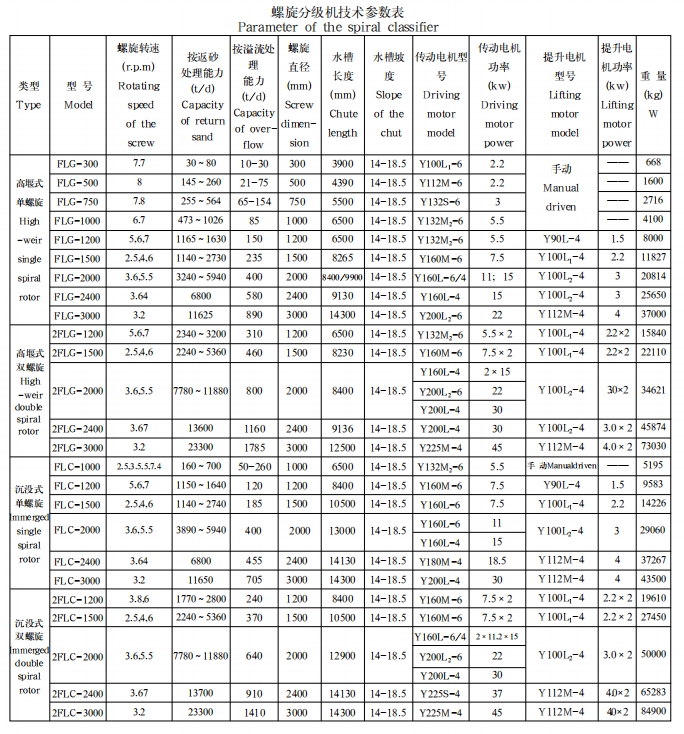

● Product parameters

The hydrocyclone group can meet the ore requirements of large mines. Our company can customize hydro