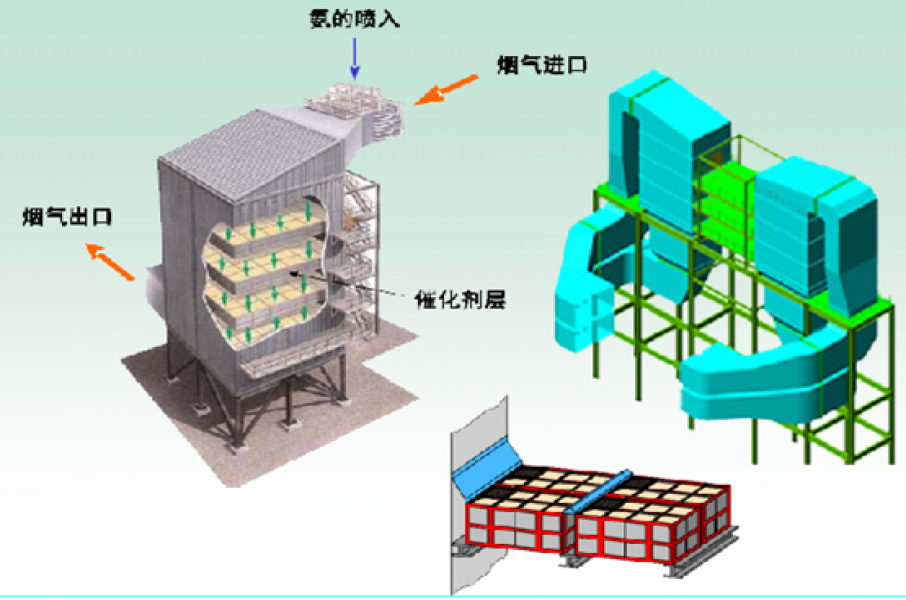

[Introduction]: De-NOx System The SCR de-NOx system consists of two major parts: the ammonia station system and the NOx area syste

The SCR denitrification system mainly includes two parts: the ammonia station system and the nitrate zone system. The ammonia station system can use liquid ammonia, urea, and ammonia water as reducing agents. The nitrate zone system can use honeycomb, plate, and corrugated plate catalysts, and various catalysts can be interchanged.

The SCR denitrification system has the following technical characteristics:

1. Spray ammonia mixing technology: adopting a "pipe hole" spray ammonia structure. Arrange the circular tube evenly perforated on the side according to the design requirements in the inlet flue of the SCR reactor. This type of ammonia spray can not only prevent high dust smoke from blocking the spray hole, but also ensure the uniform mixing of ammonia and nitrogen oxides. Reducing ammonia escape while ensuring denitrification efficiency;

2. CFD simulation: CFD simulation plays an important role in the design of SCR denitrification systems. The simulation of velocity field, temperature field, NH3/NOX mixing field and other parameters in the flue and reactor directly affects the design of flue, elbow, guide plate and other parameters, and directly affects the pressure loss, denitrification efficiency, and ammonia escape of the denitrification system.

3. Catalyst selection: Catalysts are an important and core component of denitrification systems. The performance of catalysts directly affects the normal operation of denitrification systems and the concentration of nitrogen oxide emissions.

SNCR denitration system

The SNCR flue gas denitrification system mainly includes urea storage system, urea dissolution system, solution storage system, solution buffer system, solution injection system, compressed air system, steam system, electronic control system, etc.

The SNCR denitrification system has the following technical characteristics:

1. Unique spray gun structure: The spray gun is equipped with an outer sheath to enhance its wear resistance and deformation resistance; The spray gun has the characteristics of variable flow rate and adjustable atomization air, which can reduce material consumption and minimize the impact on the decomposition furnace while ensuring denitrification efficiency; Install a compressed air blowing system at the front end of the spray gun, and by adjusting the amount of compressed air injected, form a protective film at the front end of the nozzle, thereby giving the nozzle self blocking function;

2. Compared to traditional SNCR flue gas denitrification systems, this system can use both ammonia water and urea as reducing agents, and a denitrification device can achieve the exchange of the two reducing agents;

3. The denitrification system can automatically adjust the injection amount of reducing agent through a metering pump based on the type of reducing agent, flue gas volume, nitrogen oxide concentration in the flue gas, and denitrification efficiency. This is an important means to ensure the economic operation of the denitrification system;

4. Multi layer spray gun layout form. When the temperature field inside the decomposition furnace changes, the corresponding spray gun layer is selected and put into operation according to the temperature corresponding to the spray gun layer, ensuring that the reducing agent sprayed into the spray gun is always within the reaction temperature window. This is an important technical means to ensure the operation of the denitrification system;

5. The use of CFD to simulate the various flow fields inside the cement kiln decomposition furnace has improved the accuracy of spray point selection.

The limestone-gypsum wet flue gas desulfurization system uses limestone/lime-gypsum wet flue gas des