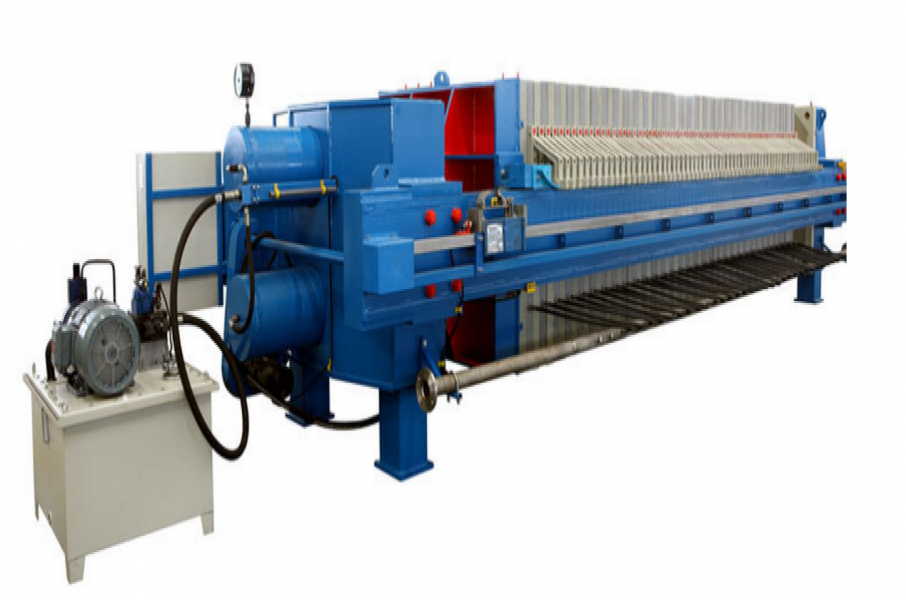

[Introduction]: Sludge Press Filter The press filter, as a solid-liquid separation device, has a long history of application in industri

As a solid-liquid separation equipment, the filter press has a long history of application in industrial production. It has good separation effect and wide adaptability, especially for the separation of viscous and fine materials, and has its unique advantages.

Filter press is an intermittent solid-liquid separation equipment, designed and manufactured with mechanical and electrical integration, with a reasonable structure and simple and convenient operation; It can achieve various processes such as pressing, holding, and loosening the filter plate. The filter chamber is composed of box type plates, filter frame plates, or arranged by box type plates. Under the pressure of the feed pump, the slurry is sent into the filter chamber, and solid and liquid are separated through the filter medium.

Widely used in chemical, dye, petroleum, ceramic, pharmaceutical, sugar, food, starch, maltose, paint, metallurgy, and sewage treatment in various industries.

The product specifications range from 250 to 2000 types, with a filtration area of 1 m2 to 1060 m2. The structure of the filter plate includes frame type and box type; Heat resistance temperature -10-100 ℃, filtrate outflow methods include open flow, dark flow, open flow external pipeline, washable, non washable, and external pipeline washing; The compression method is hydraulic compression. The filtration pressure ranges from 0.2-2.5Mpa, and the diaphragm pressure ranges from 1.0-3.5Mpa. The materials of the filter plate include cast iron, reinforced polypropylene, stainless steel, high-quality synthetic rubber, etc. The electrical components are made of branded manufacturers, and the control part is more sensitive and safe; The clamping plate, thrust plate, and machine base of the rack are all welded from high-quality steel plates, and all welded parts are shot blasted to eliminate welding stress and enhance paint adhesion, resulting in better strength and stability of the components, corrosion resistance, and long service life; It is currently the most ideal equipment in the filtration industry.

Technical parameter table

Table 1 Technical Parameters of X1000 Series Filter Press

| 项目 | XM/AZ40/1000 | XM/AZ50/1000 | XM/AZ60/100 |

1 | 过滤面积m2 | 40 | 50 | 60 |

2 | 滤板数量件 | 24 | 30 | 36 |

3 | 滤板外形尺寸 | 1000×1000 | 1000×1000 | 1000×1000 |

4 | 压紧板行程mm | 600 | 600 | 600 |

5 | 滤室厚度mm | 30-36 | 30-36 | 30-36 |

6 | 滤室容积m3 | 0.54-0.64 | 0.66-0.83 | 0.8-1.0 |

7 | 过滤工作压力MPa | 0.6 | 0.6 | 0.6 |

8 | 油泵工作压力MPa | 14 | 14 | 14 |

9 | 电动机功率KW | 5.5 | 5.5 | 5.5 |

10 | 转动方式 | 电液式 | 电液式 | 电液式 |

11 | 入料方式 | 尾端入料 | 尾端入料 | 尾端入料 |

12 | 外型尺寸mm | 3968×1440×1200 | 4388×1440×1200 | 4688×1440×1200 |

13 | 整机重量 | 4500/8415 | 4720/9040 | 4969/11000 |

表二 X1250系列压滤机技术参数

| 项目 | XMZ80/1250 | XMZ100/1250 | XMZ125/1250 | XMZ150/1250 | |

1 | 过滤面积m2 | 80 | 100 | 125 | 150 | |

2 | 滤板数量件 | 30 | 38 | 48 | 57 | |

3 | 滤板外形尺寸 | 1250×1250 | 1250×1250 | 1250×1250 | 1250×1250 | |

4 | 滤室厚度 | 聚乙烯 | 30 | 30 | 30 | 30 |

聚丙稀 | 26 | 26 | 26 | 26 | ||

球墨铸铁 | 34 | 34 | 34 | 34 | ||

5 | 滤室容积m3 | 聚乙烯 | 1.16 | 1.47 | 1.86 | 2.2 |

聚丙稀 | 1 | 1.26 | 1.6 | 1.9 | ||

球墨铸铁 | 1.3 | 1.65 | 2.1 | 2.47 | ||

6 | 压紧板行程MM | 600 | 600 | 600 | 600 | |

7 | 过滤工作压力MPA | 20 | 20 | 0.6 | 0.6 | |

8 | 油泵工作压力MPA | 20 | 20 | 20 | 20 | |

9 | 电动机功率KW | 5.5 | 5.5 | 5.5 | 5.5 | |

10 | 转动方式 | 电液式 | 电液式 | 电液式 | 电液式 | |

11 | 入料方式 | 尾端入料 | 尾端入料 | 尾端入料 | 尾端入料 | |

12 | 外型尺寸MM | 482017601555 | 531017601555 | 592517601555 | 648017601555 | |

13 | 整机重量 | 塑料 | 6775 | 7375 | 8325 | 9010 |

球墨铸铁 | 15025 | 17825 | 21435 | 24685 | ||

表三 X1500系列压滤机技术参数

| XAZ240/1500-UA | XAZ340/1500-UA | XAZ500/1500-UA | XMZ800/2000-U | XMZ1060/2000-U |

过滤面积m2 | 240 | 340 | 500 | 800 | 1060 |

滤板尺寸mm | 1500×1500 | 1500×1500 | 1500×1500 | 2000×2000 | 2000×2000 |

滤板数量(块) | 64/58 | 90/81 | 132/119 | 112-119 | 147 |

滤室厚度mm | 30 | 30 | 30 | 30-35 | 30 |

滤室容积m3 | 3.7/3.4 | 5.2/4.7 | 7.5/6.7 | 10.7-13.5 | 14.1 |

过滤工作压力MPa | ≤0.6 | ≤0.6 | ≤0.6 | ≤1.0 | ≤1.0 |

电机功率KW | 5.5 | 5.5 | 5.5 | 22/7.5/4 | 22/7.5/4 |

外型尺寸mm | 7200×2180×2200 | 8850×2180×2200 | 11470×2180×2200 | 13870×2975×2875 | 16470×2975×2875 |

设备质量Kg | 14840 | 17912 | 22830 | 48450-55000 | 57350 |

型号 | XAZ240/1500-A | XAZ340/1500-A | XAZ500/1500-A | XAZ800A/2000 | XMZ1060/2000-63 | |

过滤面积m2 | 240 | 340 | 500 | 800 | 1060 | |

滤板尺寸mm | 1500×1500 | 1500×1500 | 1500×1500 | 2000×2000 | 2000×2000 | |

滤板数量(块) | 59 | 83 | 122 | 110 | 154 | |

滤室厚度mm | 35 | 35 | 35 | 35 | 33 | |

滤室容积m3 | 3.7 | 5.3 | 7.8 | 13 | 18.1 | |

过滤工作压力MPa | ≤0.6 | ≤0.6 | ≤0.6 | ≤1.0 | ≤1.0 | |

电机功率KW | 5.5 | 5.5 | 5.5 | 22/4 | 22/4 | |

外型尺寸mm | 7200×2200×2200 | 8850×2200×2200 | 11470×2200×2200 | 14280×3140×2900 | 16800×3140×2900 | |

设备质量Kg | 40672 | 54196 | 75695 | 123250 | 159400 | |